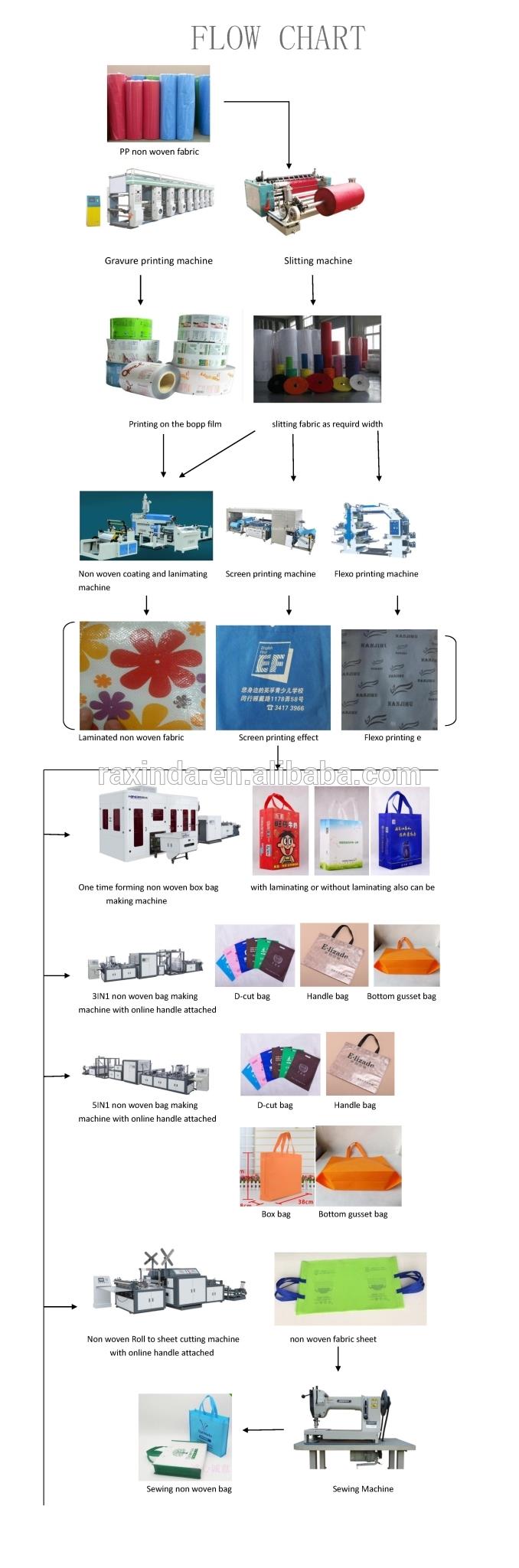

Non Woven Carry Bag Making Machine

1.Main Introductions

Fullyautomatic nonwoven bag making machine with online handle attaching, this model combined with a variety of functions, through a simple adjustment can produce different bag type, improve equipment utilization, online handle fixing reduce the bias caused by artificial iron, and effectively reduce labor costs, one touch operate make the operation more convenient, Ideal for customers with diverse orders.

2.Main Technical Parameters

|

Model |

WFB-DT600 |

|

Max.BagMakingWidth |

600mm |

|

BagMakingThicknessRange |

20-100g |

|

Max.BagMakingLength |

700mm |

|

ProductionSpeed |

40-90pcs/min |

|

TotalPower |

12kw |

|

MachineWeight |

3.0t |

|

OverallDimensions |

8500*2000*2100mm |

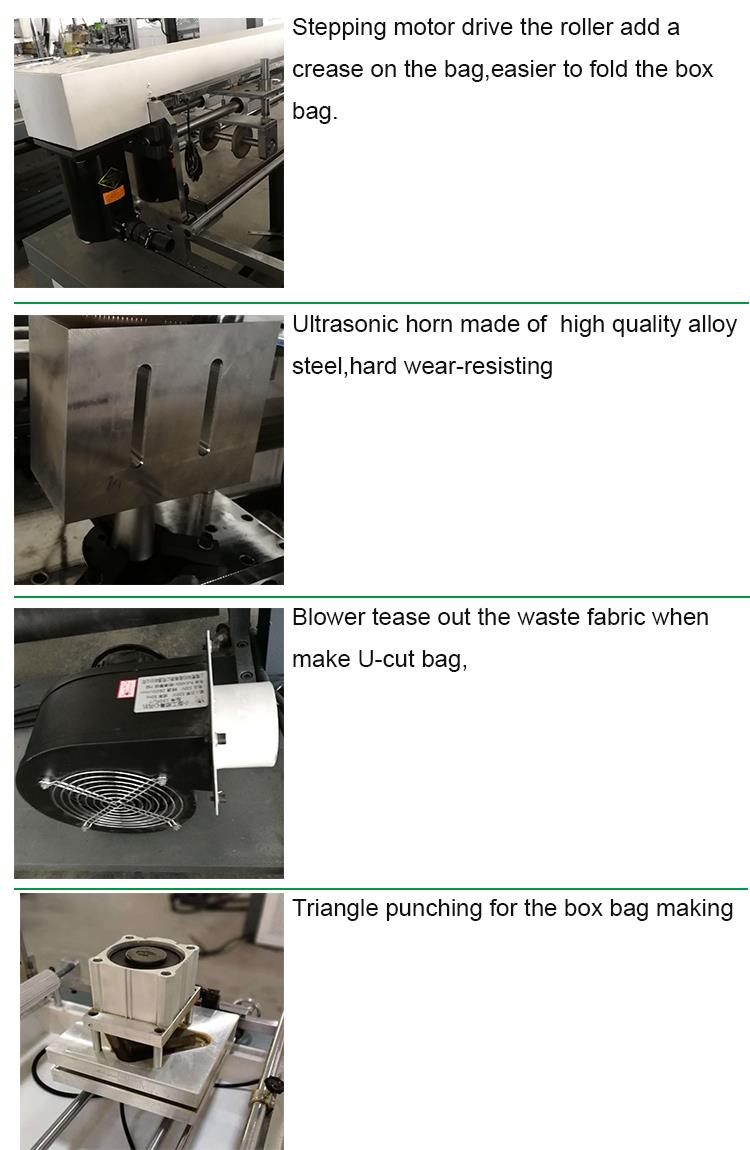

3.Detailed

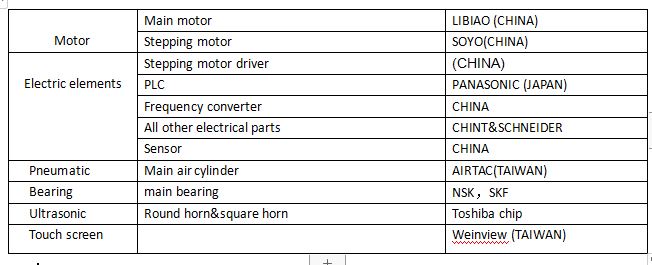

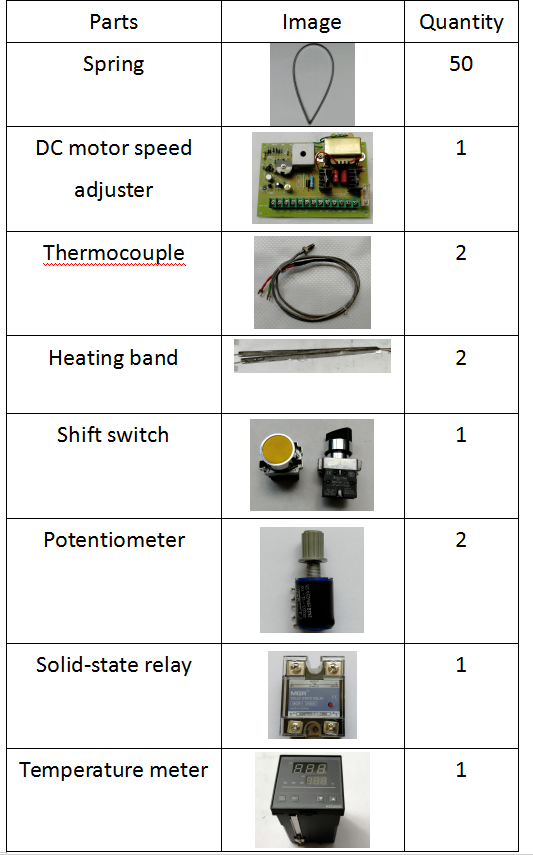

4.Main components

.

.

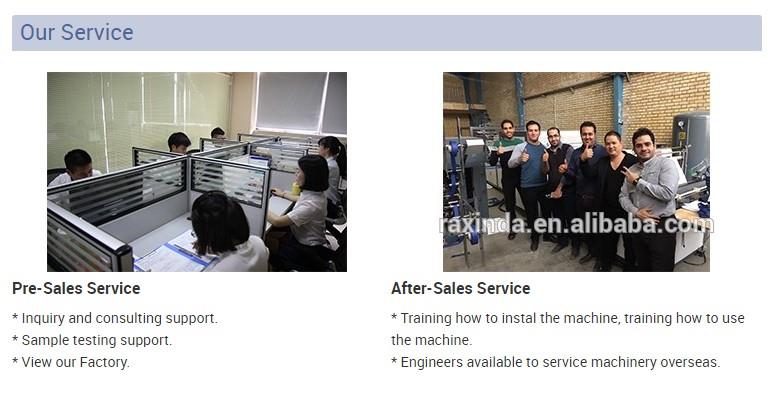

5.Service

1.Q:Why is your competitor's price cheaper than yours?

A:*The raw materials we purchase are in full compliance with national standards.

*Our machine parts are manufactured using advanced technology and processing.

*Our products are middle and high-end products in the industry, and the overall performance and stability of the machine is higher than the equivalent.

2.Q:How do you ensure the quality of machine before delivery?

A:Before delivery, the final quality control team will test the machine's performance, speed and productivity under severe conditions.

3.Q:Why should we choose your company over others?

A:At home, our products have accumulated a good reputation and brought a high quality customer base.

And we have good after-sales protection.

5.Advantage

The company creates its own brand and marketing network with advanced manufacturing technology, and provides products such as blown film machine, bag making machine to meet customer demands and related components,to help customers enhance the competitiveness of their products! Adhere to the business philosophy of "governing enterprises by virtue,establishing the world by faith " to achieve long-term operating goal that independent management,steady growth and sharing profit with employee.

For more than 15 years, we have continuously introduced new products and improved production processes and efficiency.Besides recruiting domestic elite talents, and we also introduce the latest foreign technology constantly.Looking to the future, we will meet new challenges more confidently on the existing foundation.

We look forward to establishing business relationships with all friends from all over the world!

The feeding rack is lengthened, and the maximum diameter of feeding is 20% larger than that of similar equipment, so as to reduce the feeding times and save the feeding time.

Frequency conversion motor feeding, synchronous feeding with the host, one-button operation.

The audion of the ultrasonic generator is made by Toshiba of Japan, which is stable and durable.

High-quality aluminum roller, reducing the resistance in the transmission of the cloth, so that the cloth to maintain a constant tension.

Imported bearing, low resistance.

The cutter is made of imported steel, and its durability and service life are 20% longer

7.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine