Automatic T-shirt Bag Making Machine

1.Main Introductions

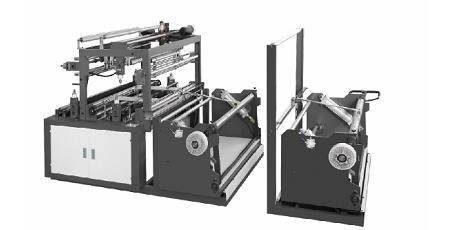

This machine is a kind of ideal equipment for non-woven fabric(with printing or not) shopping bag,U-cut bag,pillow bag,shoes bag,ribbon through bag etc.automatic punching,automatic counting and alarm,automatic loading,stop automatically when the label lost.

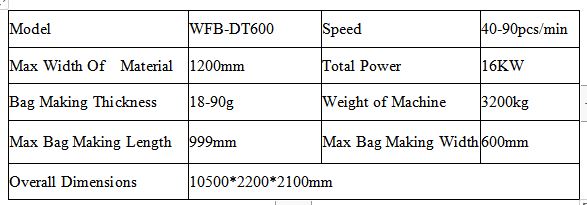

2.Main Technical Parameters

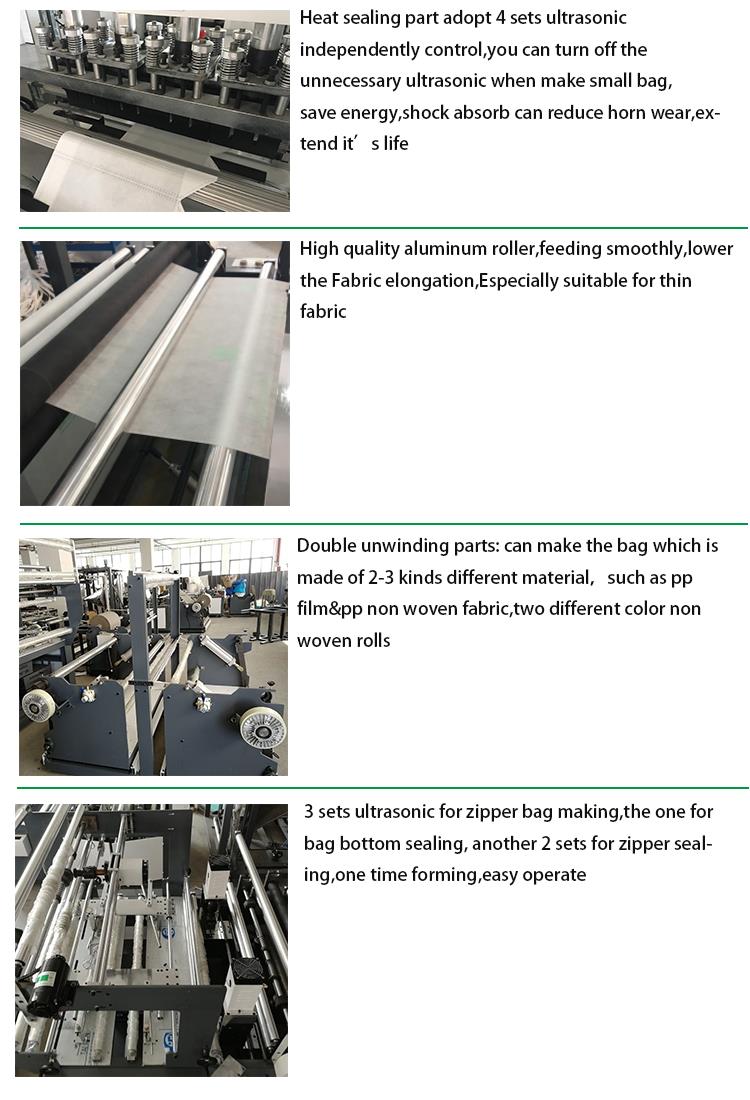

3.Detailed

|

|

4.Service

Q1. How about the quality of the machine?

A: Our comany has been making machines for more than a decade.And we have the professional person to check every detail of the machine. We have 100% test before delivery. So you can trust us.

Q2. How about your delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q3: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.

3.For the success of the first cooperation,we will give you the most favorable price.

5.Advantage

1 Imported bearing, low resistance.

2. The cutter is made of imported steel, and its durability and service life are 20% longer

3. Imported yade polite cylinder and pneumatic components. Durable and stable.

4. Low voltage electrical switch, schneider, France, stable performance.

5. Double stepping motor for material pulling, less tension, higher precision.

6. Four ultrasonic waves can be independently controlled, saving 5% of energy consumption and extending service life.

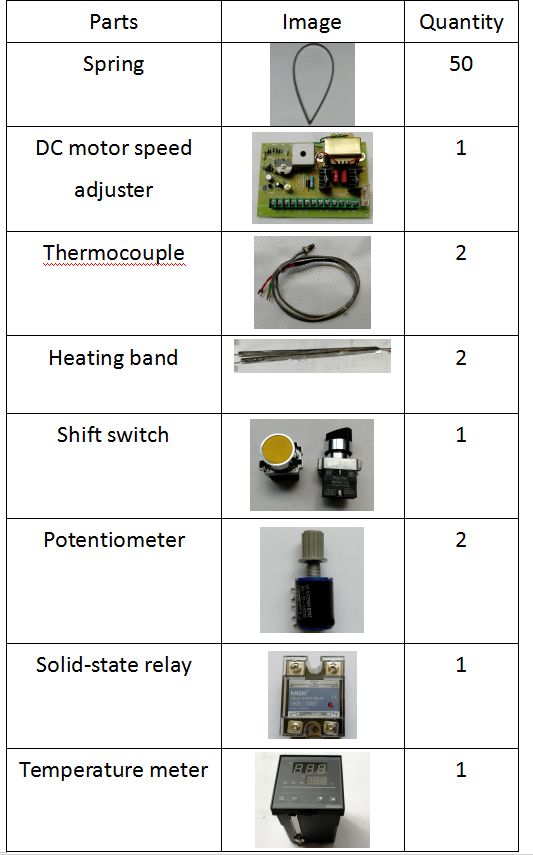

6.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

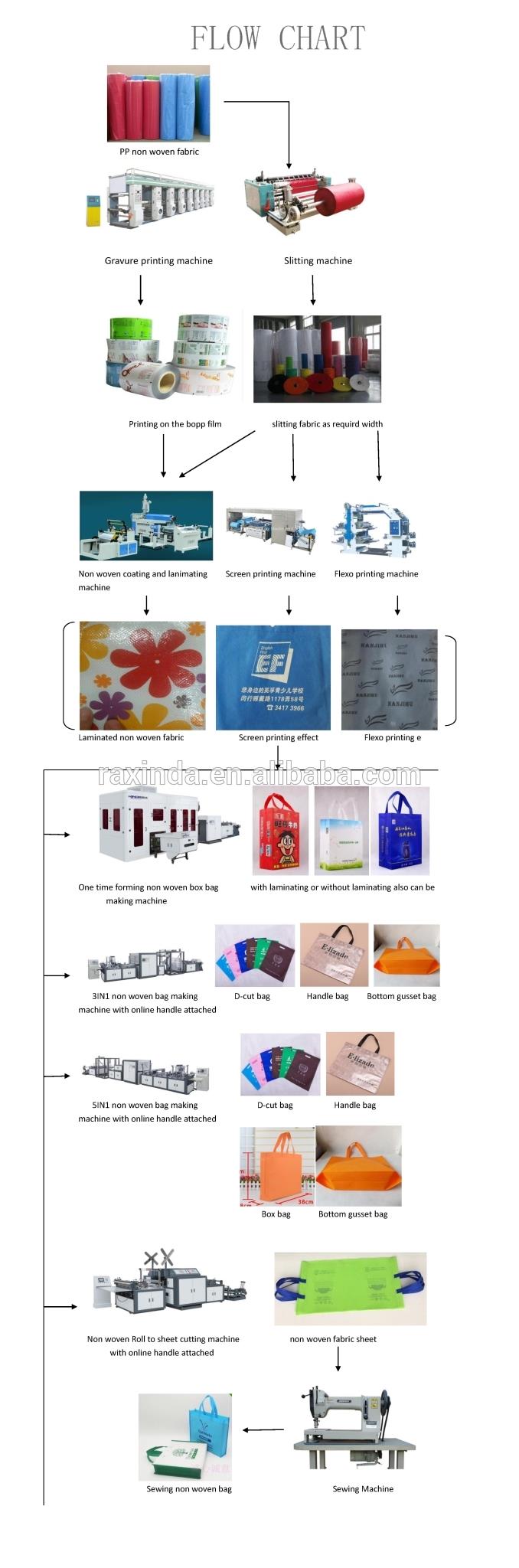

Associate machine

Main non woven machine

Bag sample

Laminated PP non woven box bag

Lamination film thickness:0.2 to 0.24cm,

Non woven thickness:90grams per square meter ,

less than general weight cotton sails tarpaulins1/10,

but its vertical and horizontal tensile strength up to30kg can be reached.

Long-term use in infrared, ultraviolet , laser and acid rain, snow or frost, ecological or other physical and chemical environment.

PP non woven box bag

Non woven thickness: 90-120 grams per square meter.

Choosing traditional printing machine printing the non woven fabric roll by roll before bag making.

Aluminum film non woven box bag

Composite materials

1. Plastic film coated with a thin layer of aluminum

2. non woven fabric

In a high vacuum state by high temperature the aluminum melt evaporated and the vapor deposition of aluminum accumulated on the surface of the plastic film so that the plastic film surface with a metallic luster .

Glitter film non woven box bag

Composite materials

1. Glitter film with printing outside

2. non woven fabric

Glitter film suitable for offset printing, gravure printing , screen printing, special printing, stamping and other processing methods.

It has been widely used in all walks of life on the packaging industry decoration market

Embossing non woven bag

Composite materials:

1. One layer of BOPP Film, One layer of Non woven fabric

2. Double layer of non woven fabric

Processing way:

1. Hot stamping BOPP film

2. Laminated BOPP film with Non woven fabric

3. Embossing the laminated material.

4. Using Allwell Leader to make the bag

PP woven bag

Composite materials:

1. One Layer of BOPP film, One layer of Woven fabric

Processing way:

1. Rotogravure printing BOPP film inside

2. Laminated BOPP film with Woven fabric

3. Using Allwell Leader to make the bag