Cheap CE Certification Brown Paper Cover Making Machine Suppliers – Shopping Bag Making Machine For Non Woven – Xinda

Cheap CE Certification Brown Paper Cover Making Machine Suppliers – Shopping Bag Making Machine For Non Woven – Xinda Detail:

1.Main introductions

At one-time finish on hand, slice, stereo into cylinder, compaction molding. It’s really solves the problem of non-woven handmade box bag high cost and slow efficiency. The finished bag compared to common bag are more beautiful and stronger. It widely used in clothing, footwear, drinks and gift packaging bag production. That can save more manual, higher efficiency, creating higher value for customers, allowing you to remain the leading in market competition.

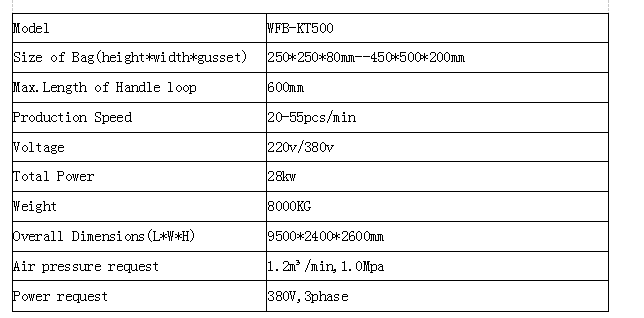

| 2.Main Technical Parameters

|

3.Detailed

4.Main Configuration

| 1)DCMotor | |||||

| 2)Thermometer | |||||

| 3)ElectricSwitch | |||||

| 4)Computercontrolsystem | |||||

| 5)Automatictrackingwholeprocess | |||||

| 6)Useadialindicatortolocatethemould | |||||

| 7)Automaticload | |||||

| 8)Automatictension | |||||

| 9)Handleloopcorrector | |||||

| 10)Automaticneatenbag |

5.Bag sample

6.Service

1.How about the quality of the machine?

Our comany has been making machines for more than a decade.And we have the professional person to check every detail of the machine. We have 100% test before delivery. So you can trust us.

2. Are you manufacturer?

Yes, we are manufacturer with more than 10 years’ experience.

3. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.

4.What is the different with other bag making machine?

It has the newesttechnology.In general case, non woven box bag made by machine need to turn around. But this machine made new non woven bag don’t need turn. It is one time finished with automatic folding part. It looks like more beautiful and efficient.

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for Cheap CE Certification Brown Paper Cover Making Machine Suppliers – Shopping Bag Making Machine For Non Woven – Xinda , The product will supply to all over the world, such as: Latvia, Thailand, Luxembourg, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!