Cheap CE Certification Paper Bag Making Machine Fully Automatic Supplier – Computer Control Non Woven Bag Making Machine – Xinda

Cheap CE Certification Paper Bag Making Machine Fully Automatic Supplier – Computer Control Non Woven Bag Making Machine – Xinda Detail:

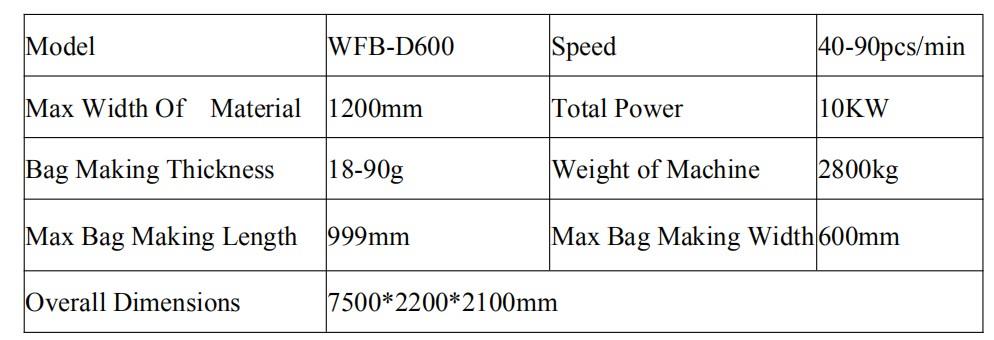

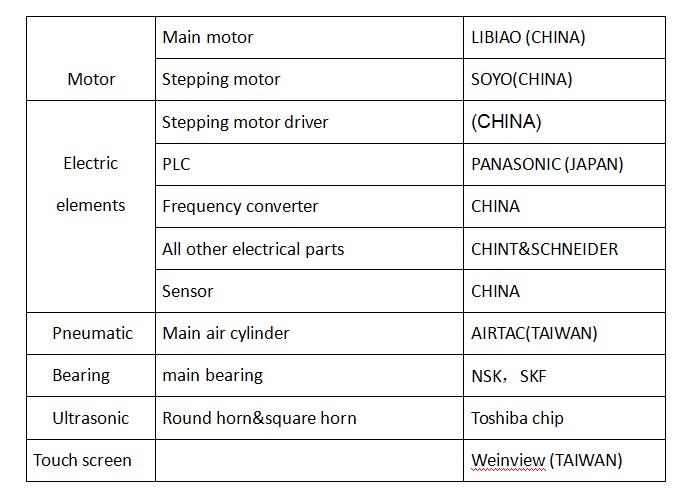

1.Main Parameter

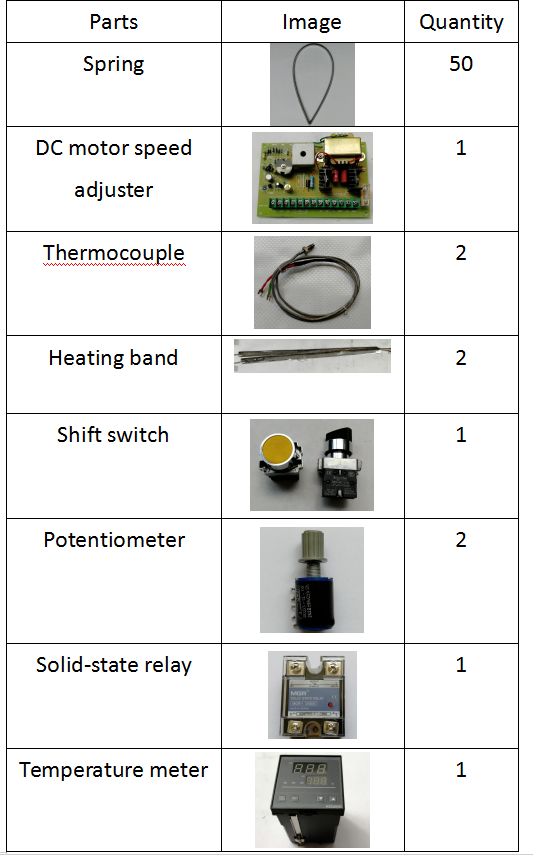

2.Main components

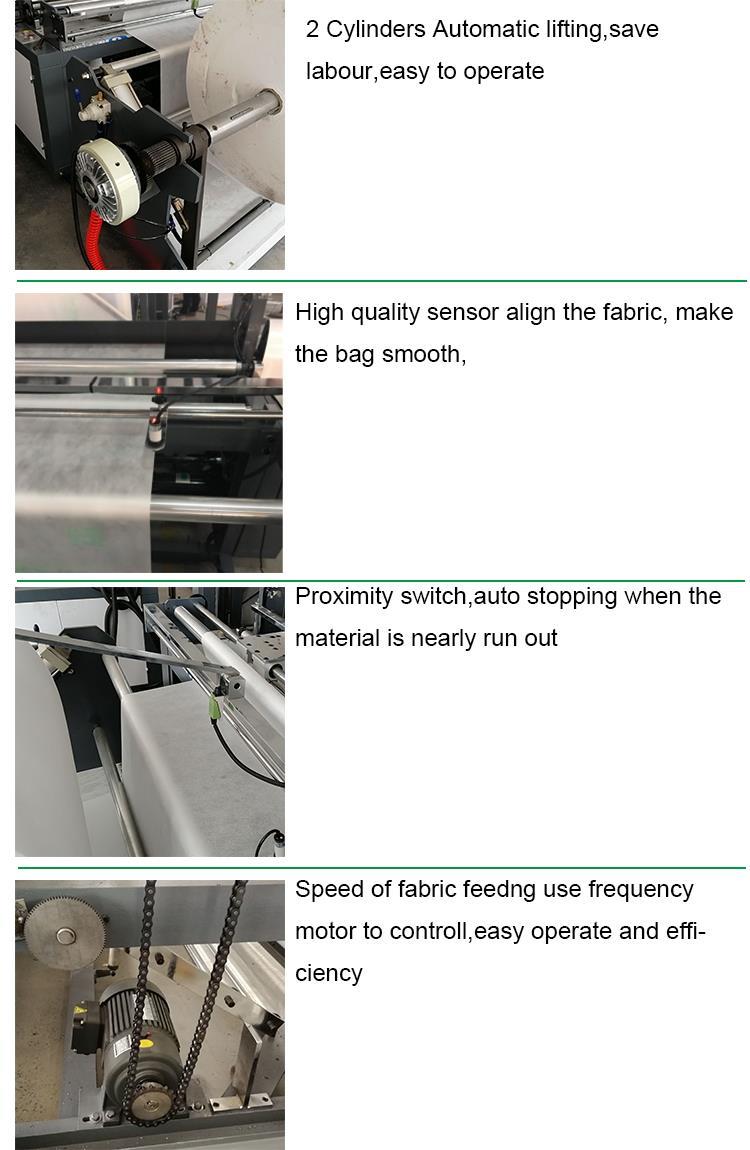

3.Detailed

4.Service

XINDA PACKING MACHINE

We have been servicing for oversea countries for 7 years. We are dedicated to making better machine of a lower price. Our company always have a conception is that customers are the first. So, from the very beginning to now, we try our best to satisfytheir need and customize special design. XINDA Machinery, your best choice.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

5.Advantage

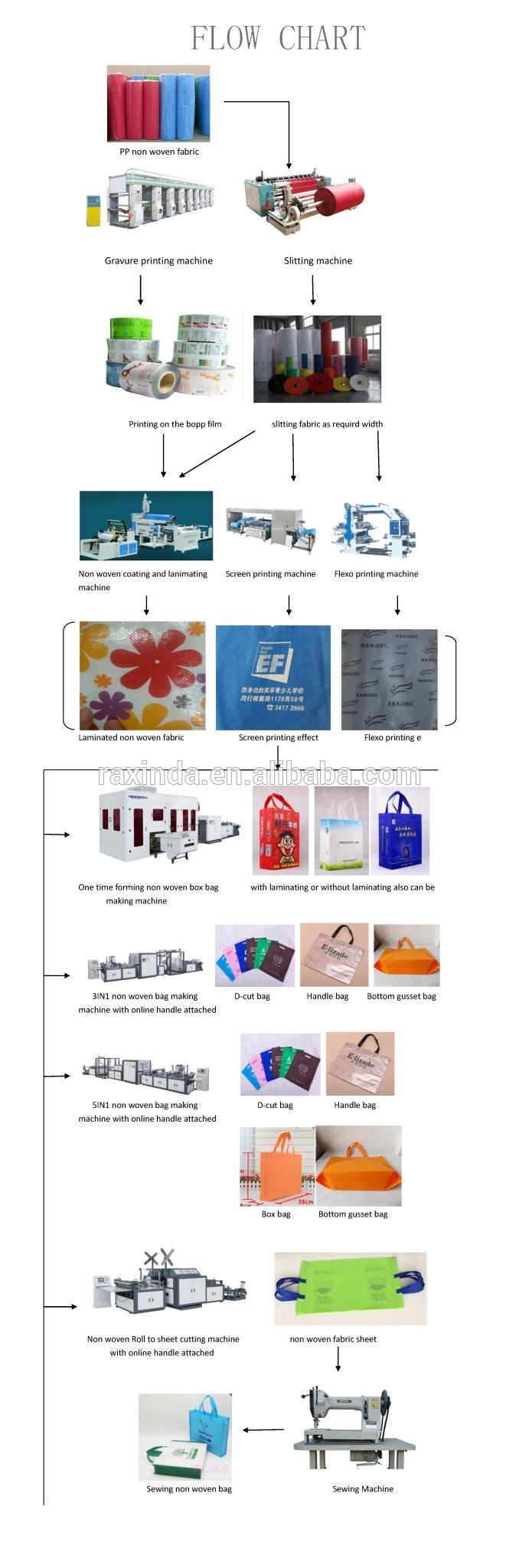

How To Make Non-woven Fabrics

The raw materials of the non-woven fabric are mainly PP granules, filler (main component is calcium carbonate), and color masterbatch (for coloring non-woven fabrics). The above materials are mixed in proportion and added to the non-woven fabric production line equipment, and are produced by high-temperature melting, spinning, paving, hot pressing and coiling in one step. In order to ensure the quality of the nonwoven fabric, the proportion of the filler is usually not higher than 30%.

The non-woven fabric has the characteristics of moisture-proof, breathable, flexible, light weight, non-combustible, easy to decompose, non-toxic and non-irritating, rich in color, low in price, and recyclable. Widely used in the production of handbags and packing bags.

6.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine

Bag sample

Can make the D-cut bag one time,combined with handle fixing machine can make handle bag

Product detail pictures:

Related Product Guide:

We love an incredibly fantastic standing amid our consumers for our superb item high quality, aggressive rate and also the finest assistance for Cheap CE Certification Paper Bag Making Machine Fully Automatic Supplier – Computer Control Non Woven Bag Making Machine – Xinda , The product will supply to all over the world, such as: Tajikistan, Mecca, Mexico, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our products have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.