Cheap CE Certification Small Scale Paper Bag Making Machine Factory – Non Woven Fabric Carry Bag Machine – Xinda

Cheap CE Certification Small Scale Paper Bag Making Machine Factory – Non Woven Fabric Carry Bag Machine – Xinda Detail:

1.Main Introductions

The finished bag compared to common bag are more beautiful and stronger. It widely used in clothing, footwear, drinks and gift packaging bag production.

That can save more manual, higher efficiency, creating higher value for customers, allowing you to remain the leading in market competition.

2.Main Technical Parameters

|

Model |

LRB-KT |

|

Size of Bag(L*W*H) |

250*100*200mm–400*160*400mm |

|

Material Thickness |

80-130g |

|

Max.Length of Handle loop |

600mm |

|

Production Speed |

20-50pcs/min |

|

Voltage |

220v/380v |

|

Total Power |

28kw |

|

Machine Weight |

3000kg |

|

Overall Dimensions(L*W*H) |

8000*2400*2800mm |

3.Service

How about the maintance and aftersales service?

Our engineer available service overseas, and we can provide remote control service and online service for

customers. But costomer has to be responsible for the accommodation and transportation costs of the technical staff.

Are you a manufacturer or trade agent?

We are the manufacture.

Is there any guarantee?

Yes, we have guarantee for the printer. We provide 13 months warranty for all the electronic parts including

the main board, driver board, control board, motor, etc, except the consumables, such asink pump, printhead, ink filter, and slide blocketc.

Can I get supplies and wearing parts from you?

Yes, we provide all the wearing parts for our printers always and they are in stock.

How will you achieve the warranty?

If any electronics or a mechanical part is confirmed to be broken, Ntek should send the new part within

48hours by express like TNT, DHL, FEDEX .etc to the buyer. And the shipping cost should be born by the buyer.

4.Advantage

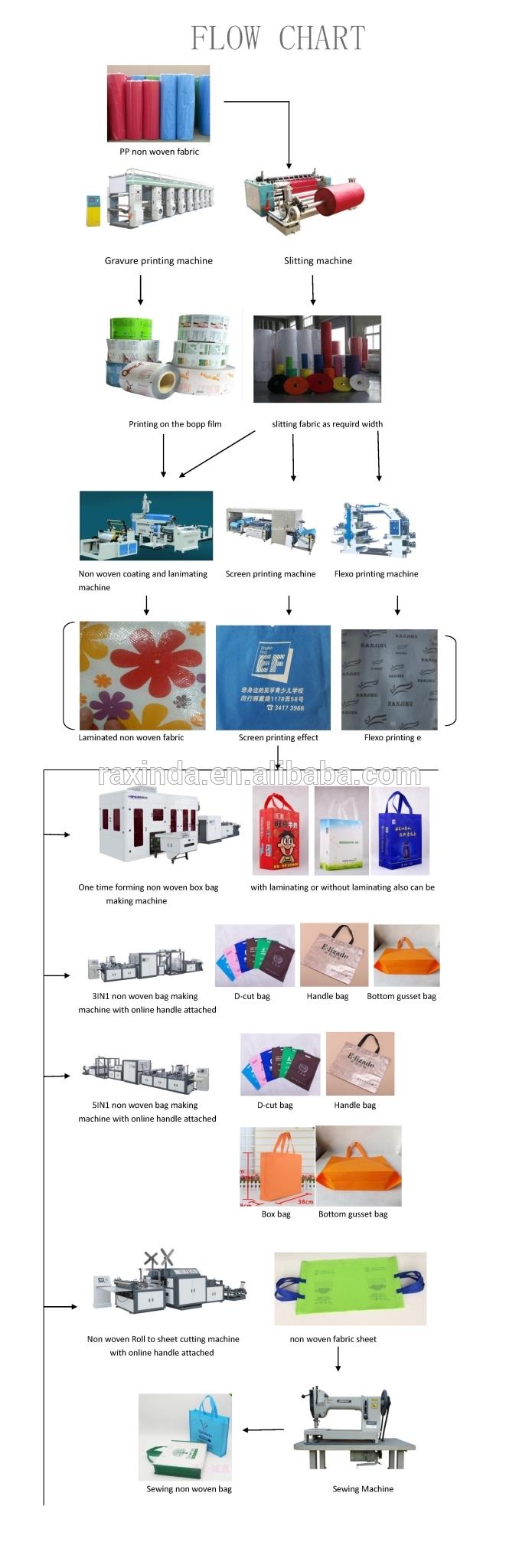

How To Set Up Non Woven Bag Making Factory

The characteristics of non woven bag are environmental protection,beautiful and durable,so it is accepted by more and more people, It's also a hot spot in the packaging market, then how to start a non woven bag factory, need to start from what aspects, the following points for you to reference.

1. Conduct market research to determine your target customers. At present, the main applications of non woven bags are: clothing bags, supermarket shopping bags, gift bags and food packaging bags.

2. Once you have identified your main customer base and product type, you need to select the equipment. At present, our non woven bag making machines are mainly divided into two categories. The first type is normal non wovenbag making machine, which are mainly used for non woven flat pocket bags,vest bags and handbags. The applicable materials are mainly normal non wovenfabric, the second type is box bag making machine, which is mainly used for normal non woven and laminated non woven.The applicable materials are normal non woven and laminated non woven.Related supporting printing equipment, mainly flexo printing, silk screen printing and offset printing.

3. Determine your investment budget and capacity requirements, and then select the final selection and ratio of equipment.

4. According to the floor space and capacity requirements of the equipment to find a suitable factory.

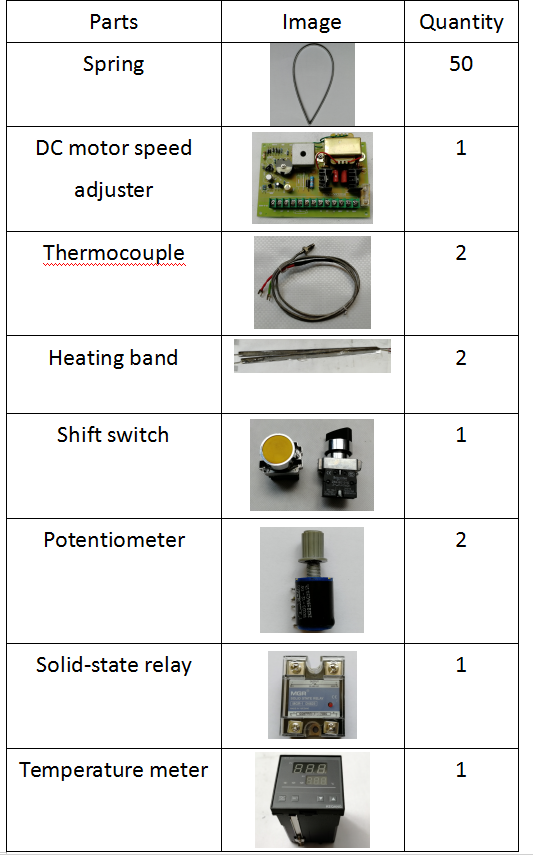

5.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine

Bag sample

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Cheap CE Certification Small Scale Paper Bag Making Machine Factory – Non Woven Fabric Carry Bag Machine – Xinda , The product will supply to all over the world, such as: Surabaya, New Orleans, Uruguay, With the first-class solutions, excellent service, fast delivery and the best price, we've won highly praise foreign customers'. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.