China High quality Carry Bag Machine Factory – Cheap Price Cloth Carry Bag Machine – Xinda

China High quality Carry Bag Machine Factory – Cheap Price Cloth Carry Bag Machine – Xinda Detail:

1.Main Introductions

Flatbag Making machine, the machine is dedicated to the production of non-woven flat bag, a single function, eliminating the need to switch different bags debugging time, so that the operation is simple, stable performance, relatively multi-functional bag making machine, the machine covers a small area, reduce plant investment costs, is very suitable for the start-up stage of the entrepreneur

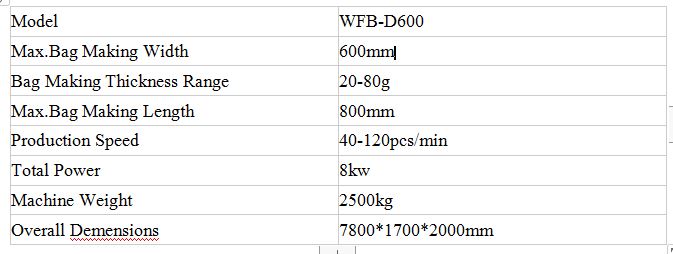

2. Main parameter

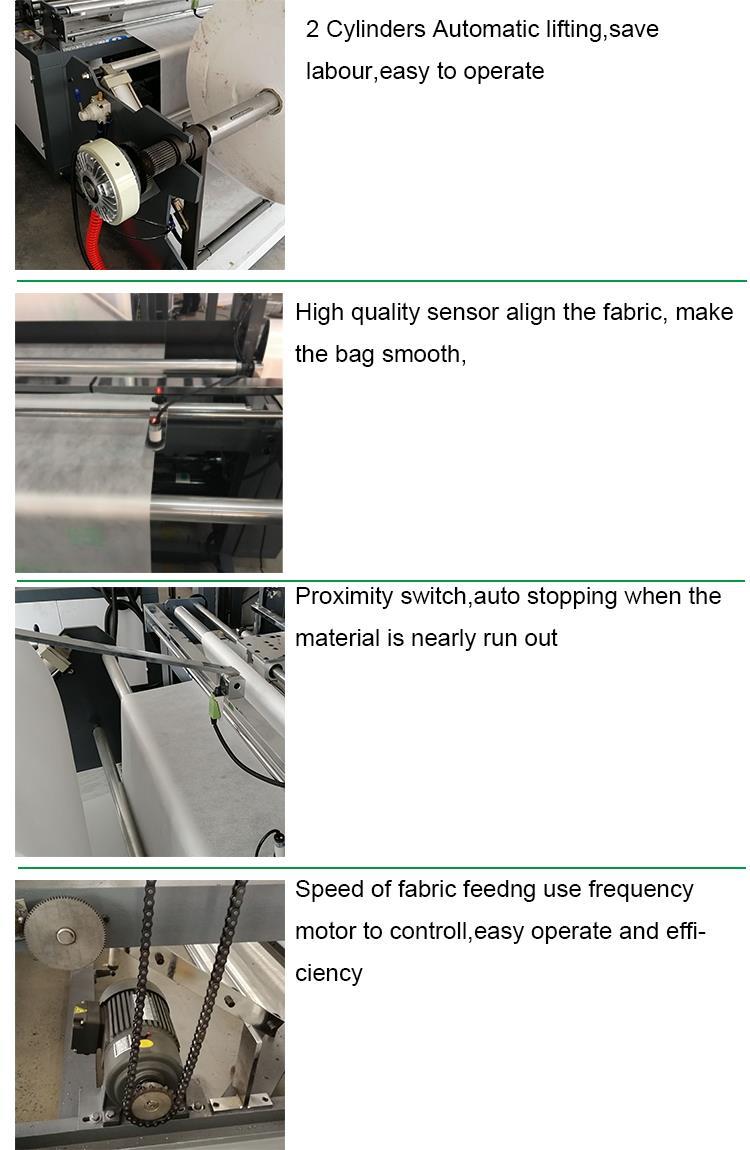

3.Main advantage and improvement

4.Advantage

1-This machine adopts Taiwan touch screen computer display,PLC computer program which can be edited.

2-Automatic counting&stopping.Could freely setting number.

3-Computer fixed-length,printing color mark track orientation,Auto-stop when complete.

4-High voltage static processor,Auto constant temoerature heating controller.

5-This machine has the function of automatic punching.

6-Unwinding magnetic powder tension control,Auto side-correction controlled.

7-This machine adopt ultrasonic welding of all aspects,bag mouth folding,side sealing,once full completed,fast speed,easy to operate,firm sealing.

5.Service

A. How many workers do we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

B. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc. Prepared)

C. How about your delivery time?

Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

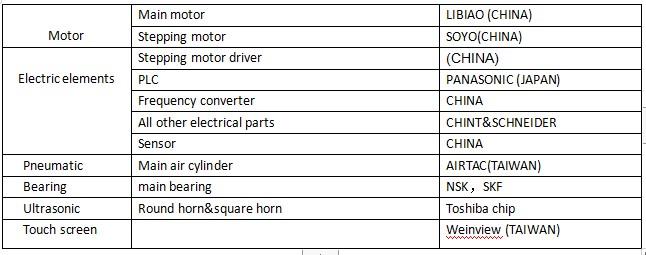

6.main components

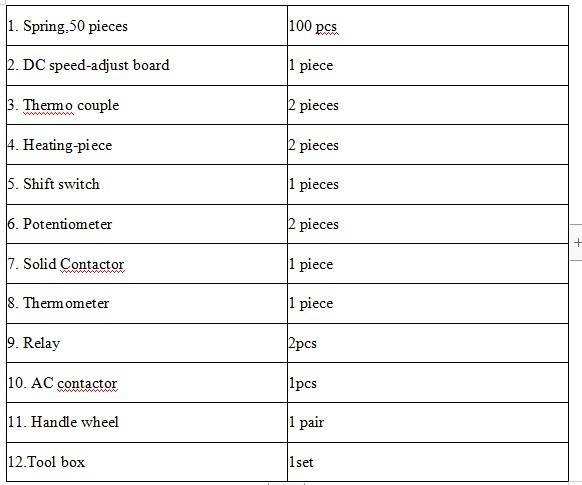

7.spare parts for free

Can make the D-cut bag one time,combined with handle fixing machine can make handle bag

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Product detail pictures:

Related Product Guide:

Adhering to your principle of "quality, assistance, performance and growth", we have now gained trusts and praises from domestic and international customer for China High quality Carry Bag Machine Factory – Cheap Price Cloth Carry Bag Machine – Xinda , The product will supply to all over the world, such as: Munich, Malta, India, Meanwhile, we're building up and consummating triangle market & strategic cooperation in order to achieve a multi-win trade supply chain to expand our market vertically and horizontally for a brighter prospects. development. Our philosophy is to create cost-effective products, promote perfect services, cooperate for long-term and mutual benefits, firm a comprehensive mode of excellent suppliers system and marketing agents, brand strategic cooperation sales system.

A good manufacturers, we have cooperated twice, good quality and good service attitude.