China High quality Cellophane Bag Making Machine Manufacturer – Non Woven Bag Making Semi Automatic Machine – Xinda

China High quality Cellophane Bag Making Machine Manufacturer – Non Woven Bag Making Semi Automatic Machine – Xinda Detail:

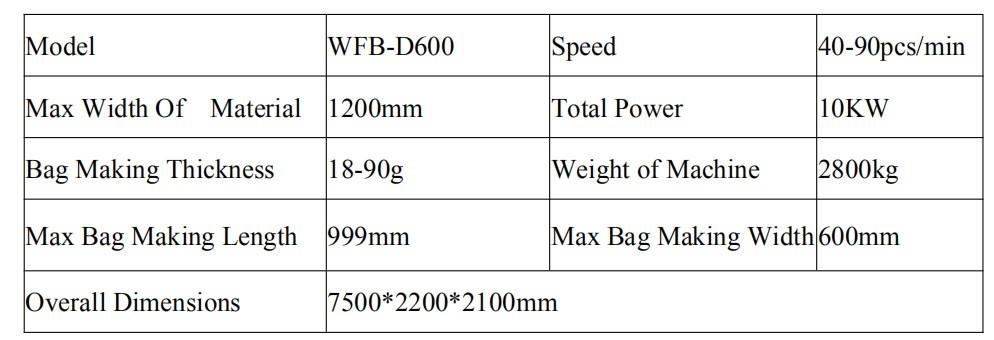

1.Main Technical Parameters

2.Detailed

|

|

|

HIGH QUALITY ULTRASONIC |

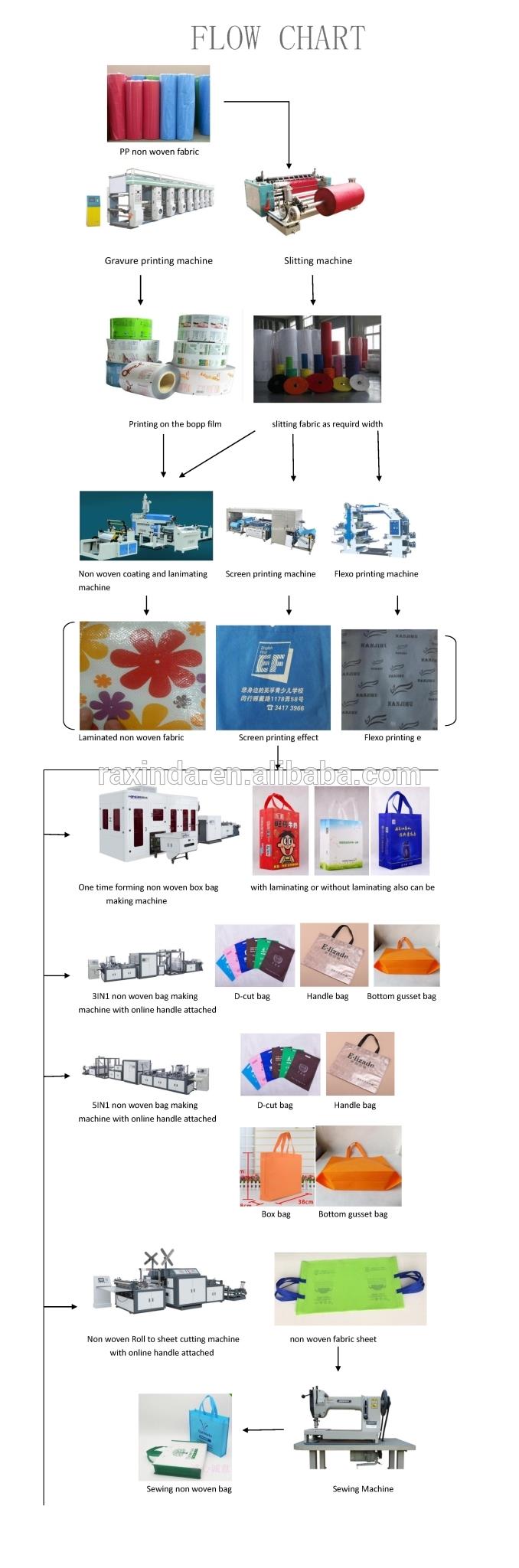

3.Bag sample

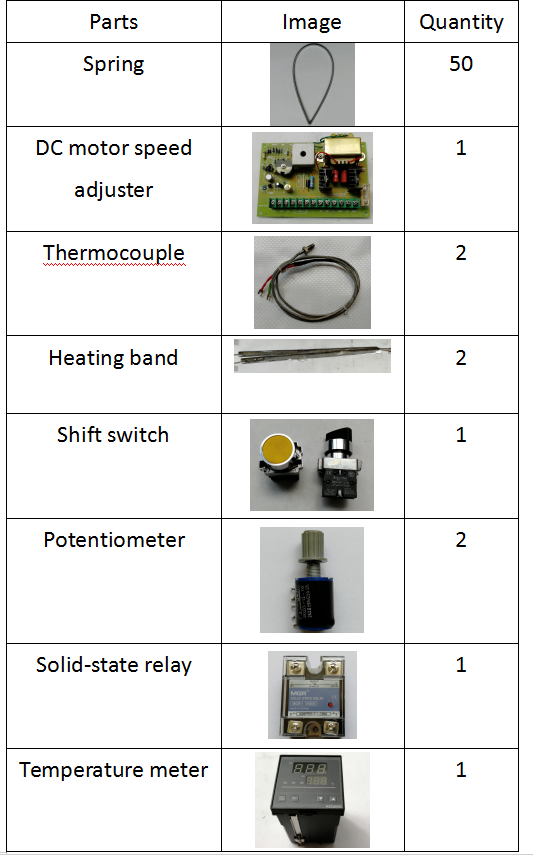

4.Main components

5.Service

1.How long will your engineer reach our factory?

Within one week aftereverything ready (machine arrival your factory, non woven material, power source, air compressor etc.Prepared)

2. How many days will you finish installing ?

We will finish installation and training within 15 days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer’s air tickets, hotel,food,and also their salary80USD one day per person.

4. How long is your machine’s warranty period?

All our machine have one year guaranteefor electricity parts and two years guarantee for mechanism, starting from finished installation.

5. How couldyoudo after one year warranty period?

We also can do service for you, but you need pay salary forourtechnicians80USD/dayfor each person.

6. How couldyoudo if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

7. Does your engineer understand English?

Our engineersunderstand a little English. All our engineershave more than five years machine installationexperience. In addition, they can use body language to communicate with customer.

8. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

9. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finishinginstallation. In case you have any problem, you can contact our sales at any time. Our engineerswill take a solution video according yourdescription.

10. How many workersdo we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punchingmachine only need one person for each.

6.Advantage

1).It’s a ideal equipment for producing non-woven flat bag, D-cut bag, shoes bag and handle bag.

2). Adopts top brand electricity, optical and pneumatic components, features reliable, long working life and easy maintenance.

3). All the bags adopts thermal bonding by ultrasonic welding(Taiwan top brand ultrasonic device), features strong sealing effective, high speed, tidy and environmental friendly.

4). With experienced engineers and well-trained technical workers and continuous innovation and reform, ensure our machine’s quality and mechanical stability.

5). Equipped with auto loading device, Taiwan touch screen, computer control, auto feeding, counting and stopping, easy to operate, one or two person can handle it easily.

6). With CE certification and ISO9001 certification.

7.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine

Product detail pictures:

Related Product Guide:

Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for China High quality Cellophane Bag Making Machine Manufacturer – Non Woven Bag Making Semi Automatic Machine – Xinda , The product will supply to all over the world, such as: Brunei, Hyderabad, Burundi, With well educated, innovative and energetic staff, we are responsible for all elements of research, design, manufacture, sale and distribution. By studying and developing new techniques, we are not only following but also leading fashion industry. We listen attentively to the feedback from our customers and provide instant replies. You will instantly feel our professional and attentive service.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.