China High quality Foam Bag Making Machine Manufacturer – Automatic Non Woven Fabric Roll Cutting Machine – Xinda

China High quality Foam Bag Making Machine Manufacturer – Automatic Non Woven Fabric Roll Cutting Machine – Xinda Detail:

1.Main introduction

This machine combine the cutting machine and sewing machine together,can do the cutting and handle sewing one time.control by plc,automatic loading,automatic counting,automatic alarm.easy operate and high efficiency.

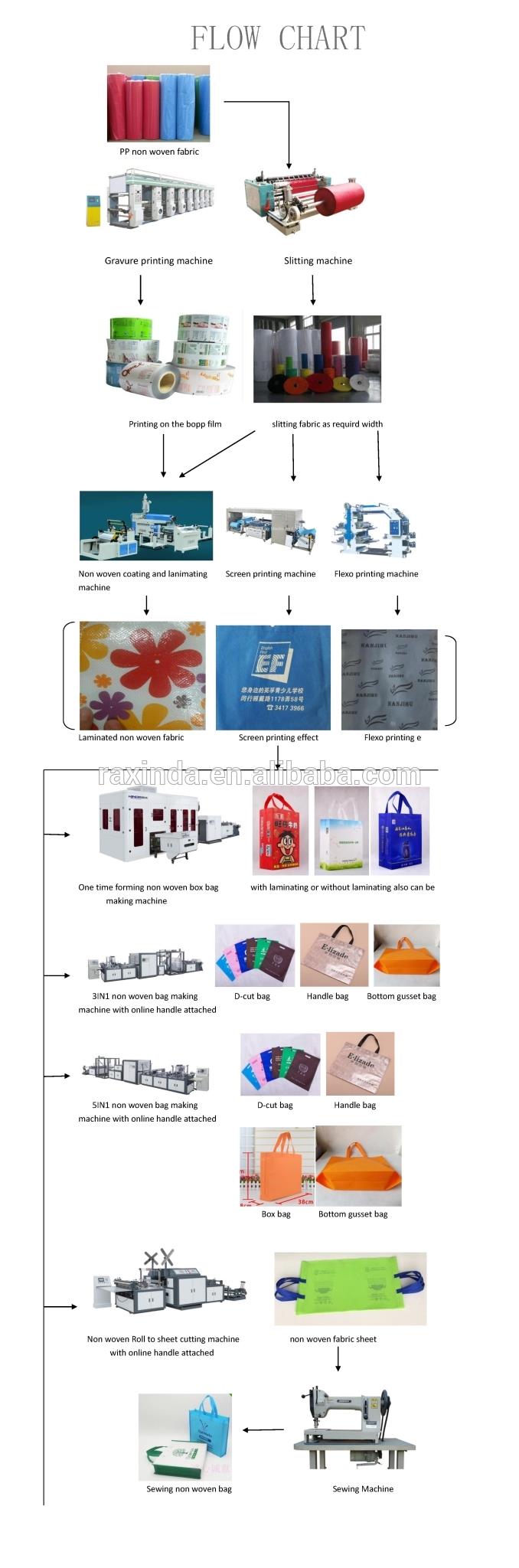

Process flow:

Automatic lifting—automatic align device—material feeding—bag mouth folding&sealing—handle pre-attaching –tension adjust-sewing-cutting

2.Main parameter

| MODEL | XD-SC1200B |

| Max-Bag Making Width | 1200mm |

| Bag Making Thickness Range | 20-100g |

| Max-Bag Making Length | 999mm |

| Production Speed | 40-80 |

| Total Power | 10kw |

| Machine Weight | 2600kg |

| Overall Dimensions | 5000X2200X1700mm |

3.Main configuration

Cutting part

1. Main motor Frequency motor with converter

2. Control by Plc&touch screen

3. Material pulling with servo

4. Material feeding with frequency motor &converter

5. Bag mouth sealing by ultrasonic

6. Automatic loading parts&align device

7. low-voltage electric

8. sensor

sewing part

High speed industrial sewing machine- Servo motor drive sewing machine Pulling with servo motor

Length control by steeping motor

4.Main components

|

Motor |

Main motor | LIBIAO (CHINA) |

| Stepping motor | SOYO(CHINA) | |

| Servo motor | Elesy (CHINA) | |

|

Electric elements |

Servo motor driver | (CHINA) |

| PLC | PANASONIC (JAPAN) | |

| Frequency converter | CHINA | |

| All other electrical parts | SCHNEIDER | |

| Sensor | CHINA | |

| Pneumatic | Main air cylinder | AIRTAC(TAIWAN) |

| Bearing | main bearing | NSK,SKF |

| Ultrasonic | Round horn&square horn | Toshiba chip |

| Sewing machine | Japan | |

| Touch screen | Weinview (TAIWAN) |

5.Service

1.What about the after sales service?

We offer the Preventative Maintenance and After Sales Service. For we strongly feels that importance of supporting our customers and the product solutions we provide. Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

2.Can we order on alibaba.com?

Of course! We will give you more discount if you order on alibaba.com.

3.How does your factory do regarding quality control?

Quality is the most important principle. GREAT WALL always attaches great impartance to quality controlling from the every beginning to the every end. Our factory has passed CE certifications.

6.Advantage

Main advantage

1. Main motor&material feeding adopts frequency motor,synchronous control,make sure the constant tension.

2. Feeding material use servo motor,closed-loop control,suitable for different thickness material,lower it’s elongation,

3. Automatic lifting part adopts air cylinder,suitable for the big and heavy roll,save time save labor

4. Chip of ultrasonic made in japan,high quality and durable 5.Whole equipment control by plc,one-touch control,easy operate

6.Machine frame use international standard U-steel,strong& durable,can reduce the shake with machine high speed running ,ensure the precision 7.Sewing machine drive by servo motor,high speed,more stability,with neatly stitching and uniform stitching length

8.Automatic alarm for break line,reduce waste

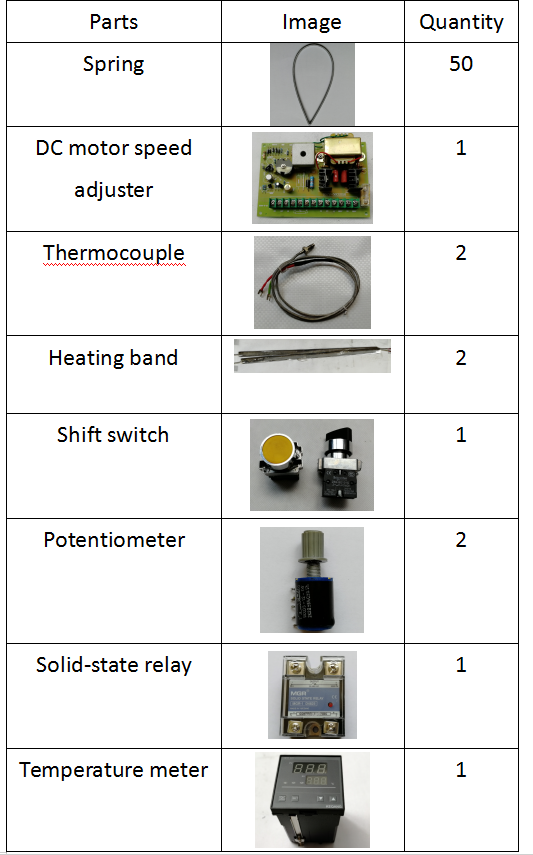

7.Spare parts for free

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine

Fine quality management pay attention to every detail of the equipment manufacturing process

We have established stringent spare parts quality management standards, some key spare parts use well-known foreign brands to ensure he high performance of each machine, low figure rate, durability, simple and convenient operation and maintenance, every detail from the customer’s consider the angle

Product detail pictures:

Related Product Guide:

The client satisfaction is our primary concentrate on. We uphold a consistent level of professionalism, top quality, credibility and service for China High quality Foam Bag Making Machine Manufacturer – Automatic Non Woven Fabric Roll Cutting Machine – Xinda , The product will supply to all over the world, such as: Canada, Swiss, belarus, With nearly 30 years' experience in business, we are confident in superior service, quality and delivery. We warmly welcome customers from all over the world to cooperate with our company for common development.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!