China High quality Paper Bag Making Machine Small Scale Factories – SS Non Woven Fabric Making Machine – Xinda

China High quality Paper Bag Making Machine Small Scale Factories – SS Non Woven Fabric Making Machine – Xinda Detail:

Product name:

SS-3200 PP SPUNBOND NONWOVEN FABRIC MAKING MACHINE

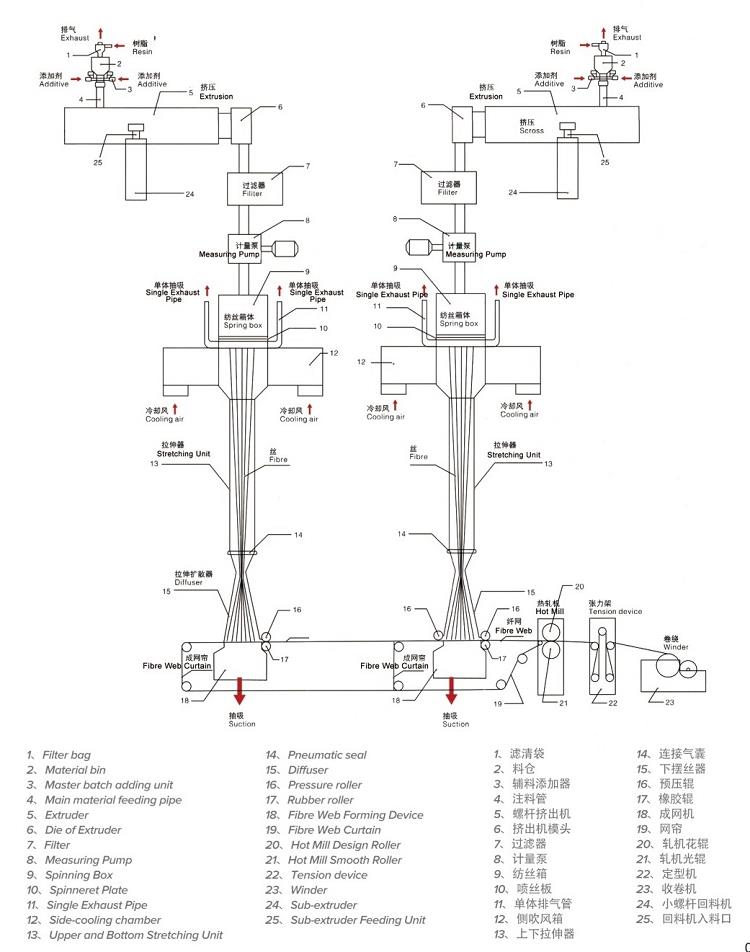

1.process flow:

Feeding→Extrusion Melting→filtering→metering→spinning→Cooling→Stretching →Web spreading→Thermal bonding→slitting→collecting

2. Product characteristic:

2-1 Product PP spunbonded nonwovens

2-2 Product width:3200mm (final nonwoven product)

2-3 Product gram 14-120 g/m2

2-4 Filament titer: ≤2.5 Denier

2-5 Production capacity:18T/Day (Based on fabric≥40g/m2 )

3. raw material specification

3-1 Melting index (g/10min)20-40

3-2 Melting point(0C)165

3-3 Molecule uniformity degree(%) >95

3-4 Gray proportion(PPM) <200

4.Utilities

4-1 Electricity: 1312KW for full line,working power: 495KW

| SN | Main electric equipment | Working power | Coefficient |

| 1 | Feeding Fan | 5.5KW×2 | 0.5 |

| 2 | Master match meter | 0.75 KW×6 | 0.4 |

| 3 | Extruder | 110 KW×2 | 0.4 |

| 4 | Metering Pump | 5.5 KW×2 | 0.5 |

| 5 | Hot oil cycle system | 4 KW×4 | 0.6 |

| 6 | Web former & preheating roller | 36 KW×1 | 0.3 |

| 7 | Calender | 22 KW×2 | 0.5 |

| 8 | Oil cycle system | 5.5KW×1 | 0.6 |

| 9 | Rewinder | 15KW×1 | 0.6 |

| 10 | Slitter | 11KW×1 | 0.3 |

| 11 | Side cooling blower | 75KW×3 | 0.4 |

| 12 | Suction blower | 55KW×1 | 0.50 |

| 13 | Cooling system | 100KW×1 | 0.5 |

| 14 | Water cooling towel | 15KW×1 | 0.6 |

| 15 | Calciner | 38 KW | 0.3 |

| 16 | Ultrasonic cleaner | 2 KW | 0.4 |

| 17 | Electric block | 2 KW | 0.2 |

| 18 | Workshop lighting | 10KW | 0.5 |

| 19 | Heating system | 492 KW×1 | 0.4 |

| 20 | Scrap recycle extruder | 18.5 KW×2 | 0.3 |

4-2 Water: 160m3/hr circulation water, 1T/day consumption

4-3 Compressed air: 1m3/min. pressure 0.8Mpa

4-4 The buyers’ responsible part:

A.Plant building: 25x12x11 M

B.The power sent to each equipment controlled cabinet

C.Water sent to the equipment and the lighting Configuration of the plant

D.The stuffs, hoisting equipment and installation material and equipments required

during installation.

(Buyer should supply accommodation and salary of supplier’s technicians.)

5. Detailed image

|

|

|

|

|

|

6.Service

Service:

A.Lsupportsourcustomersservice24hoursAday,7dayswork,Anyinquirycould

berepliedwithin1hourpre-salesandafter-sales.

WeBelievethatonly:BestQualityMachineWithInnovativeIdeasandExcellentAfter-saleService:”shallmeetyourspecialrequirements.

7.Advantage

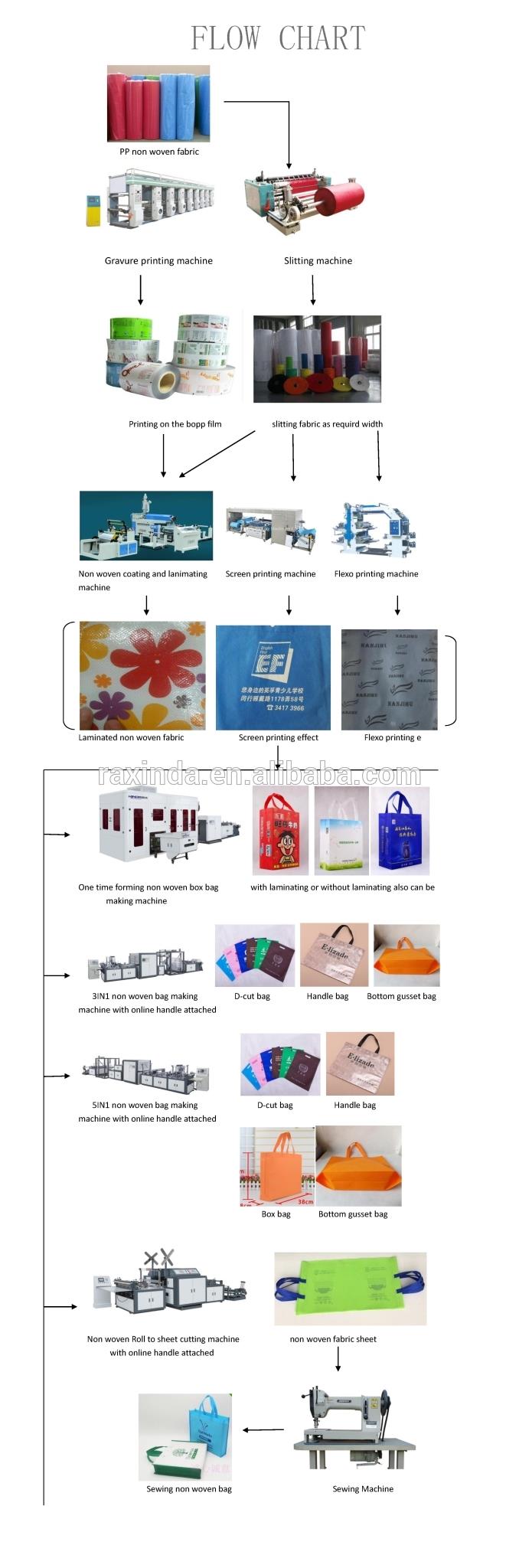

Nonwoven fabric usage:

(1)Medical and health usage:operation suit,garment,face mask,diaper,sanitary napkin,disposable hygiene product.etc;

(2)Home decoration:shopping bag,wall covering fabric,table cloth,bed sheet,bedspread.etc;

(3)Lining for clothes or shoes:lining,adhesive interlining,shoe lining.etc;

(4)Agricultural usage:Protection cover,nursery cover.etc;

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine

Fine quality management pay attention to every detail of the equipment manufacturing process

We have established stringent spare parts quality management standards, some key spare parts use well-known foreign brands to ensure he high performance of each machine, low figure rate, durability, simple and convenient operation and maintenance, every detail from the customer’s consider the angle

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for China High quality Paper Bag Making Machine Small Scale Factories – SS Non Woven Fabric Making Machine – Xinda , The product will supply to all over the world, such as: Botswana, St. Petersburg, Turin, Our company sets up several departments, including production department, sales department, quality control department and sevice center,etc. only for accomplish the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers,because you win,we win!

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.