China High quality Plastic Bag Cutting Machine Factories – Non Woven Fabric Roll to Roll Screen Printing Machine – Xinda

China High quality Plastic Bag Cutting Machine Factories – Non Woven Fabric Roll to Roll Screen Printing Machine – Xinda Detail:

Product Name:

automatic roll to roll screen printing machine for nonwoven fabric

1. Main introductions

This screen printing machine is new design screen printing machine under the feedback from customer and improve the use. With balanced pressure and thick ink, is suitable for above 45 gsm non woven fabric printing. More high-quality printing. Big-size printing area to print multiply layouts

2.main advantage

1. Automatic feeding printing, drying and collecting. Save labors and overcome restraints casused by weather conditions.

2. With Balanced pressure, with high ink thickness. Suitable for printing on high-quality non-woven products.

3. Applied to various sized of printing screen frames.

4. Big-zise printing area to print multiply layouts. Improve work efficiency.

5. Before and after full page printing, effective space between images can be reduced to minimum 1 cm.

6. High precision of printing sontrolled by servo motor.

7. Support non woven bag making more automatically and greatly improve work efficency..

3. Machine Specification

|

SN |

Item |

Specification |

|

1 |

Max printing size |

1200×1100 mm |

|

2 |

Non woven fabric roll width |

1250 mm |

|

3 |

Non woven fabric thickness |

45-100 gsm |

|

4 |

Max diameter of roller |

800 mm |

|

5 |

Printing speed |

700-1200 m/h |

|

6 |

Power supply |

380V 3P4N |

|

7 |

Total power |

28KW |

|

8 |

Rated power |

13KW-14KW |

|

9 |

Overall size |

L 7500* W 1800* H 1720mm |

|

10 |

Weight of Machine |

4000KGS (40HQ*1) |

4.Sample

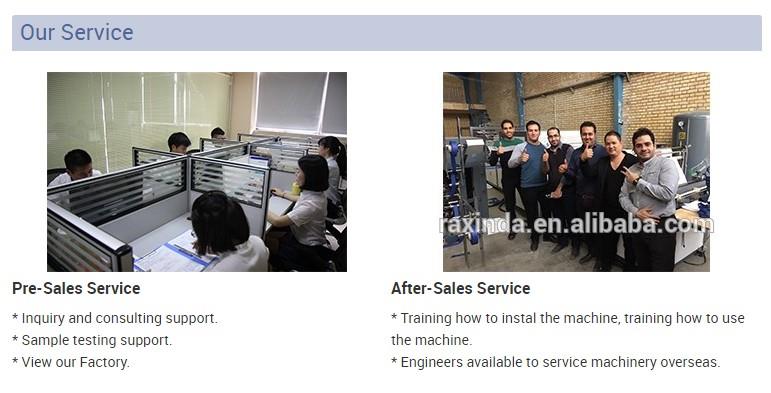

5.Service

1. How long will your engineer reach our factory?

Within one week after machine arrival your factory.

2. How many days will you finish installing ?

We will finish installation and training within 15days.

3. What should we charge for your engineer?

You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 50USD one day per person.

4. How long is your machine's warranty period?

All our machine have one year guarantee, starting from finished installation.

5. How could we do after one year warranty period?

We also can do service for you, but you need pay salary for my technician 80USD/day.

6. How could we do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

7. Does your engineer understand English?

Our engineer understand a little English. All our engineer have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

8. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

9. How do we solve the machine problem after your engineer leaving?

Generally speaking, there will be no problem after finish installing. In case you have any problem. You can contact our sales at any time. Our engineer will take a solution video according your description.

10. How many worker do we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

6.Advantage

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

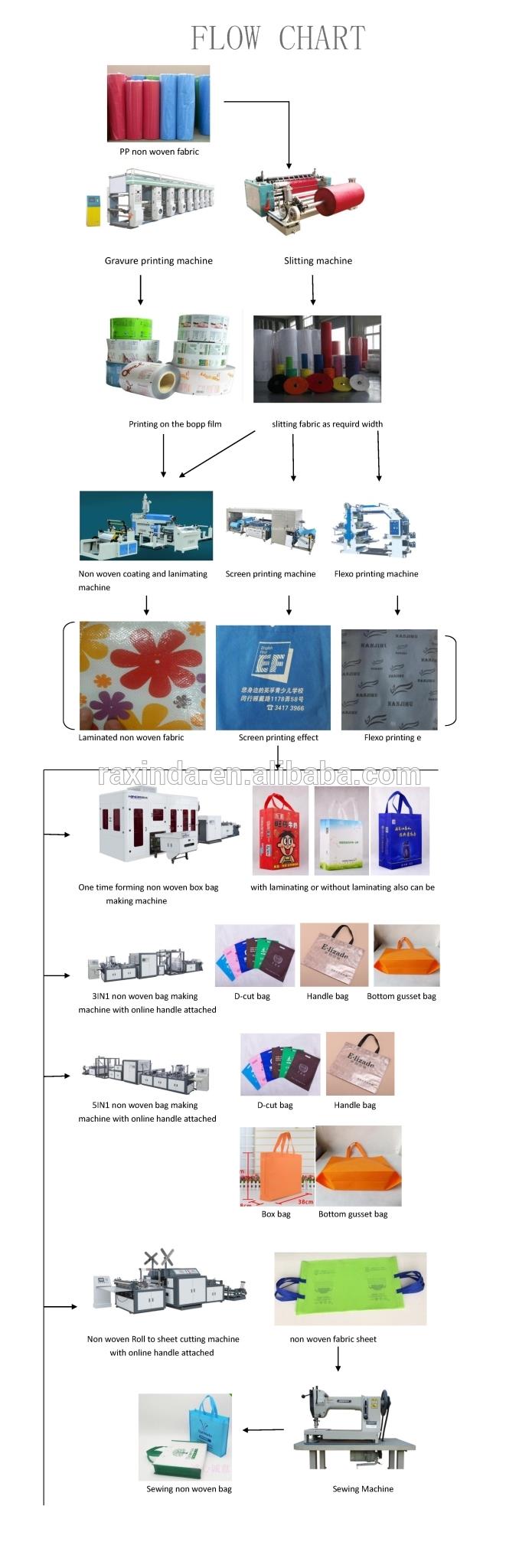

Associate machine

Main non woven machine

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for China High quality Plastic Bag Cutting Machine Factories – Non Woven Fabric Roll to Roll Screen Printing Machine – Xinda , The product will supply to all over the world, such as: Estonia, Madagascar, Nicaragua, We've customers from more than 20 countries and our reputation has been recognized by our esteemed customers. Never-ending improvement and striving for 0% deficiency are our two main quality policies. Ought to you want anything, don't hesitate to contact us.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.