China High quality Pvc Blow Molding Machine Factory – Fabric Lamination Machine – Xinda

China High quality Pvc Blow Molding Machine Factory – Fabric Lamination Machine – Xinda Detail:

Product name:

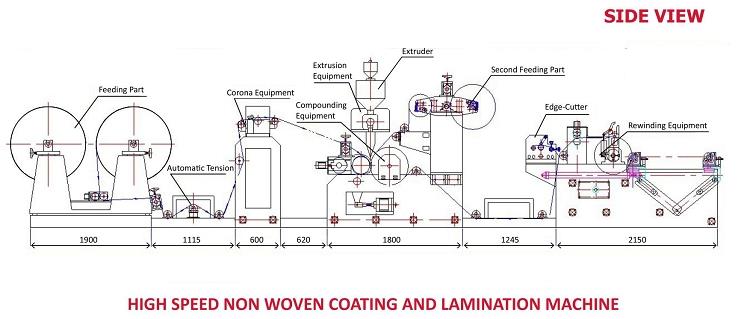

high speed extrusion & laminating machine for nonwoven fabric

1.Main introduction

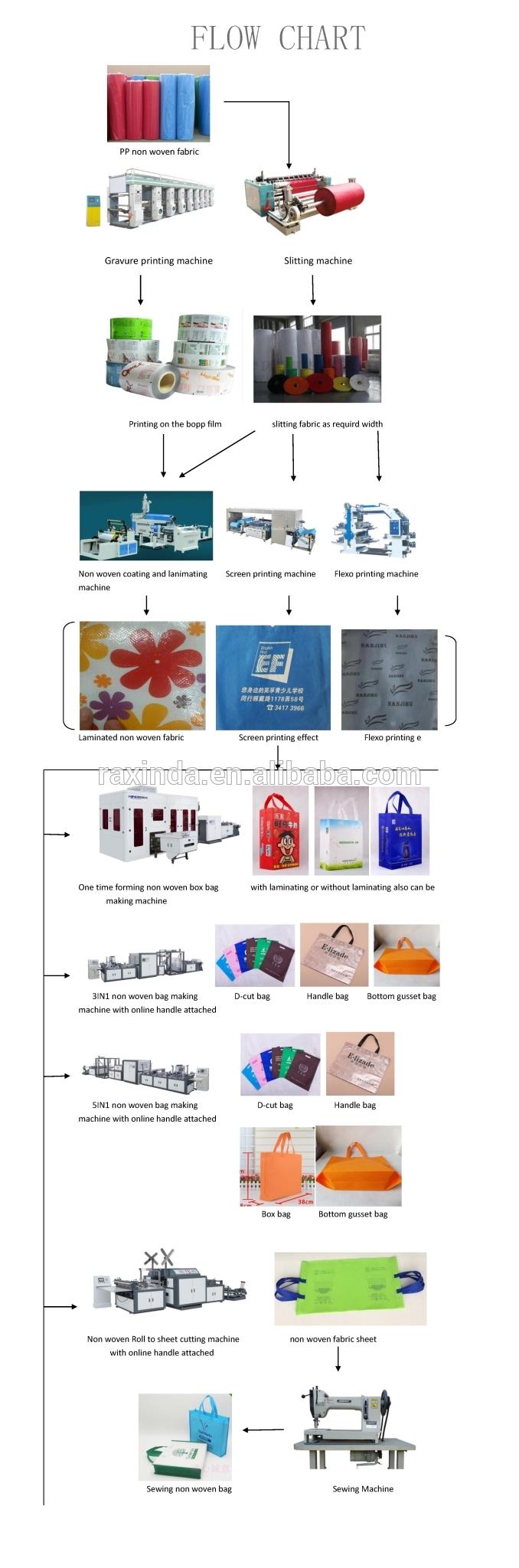

XD-L series hot melt adhesive laminating machine is used for producing self-adhesive products, such as self-adhesive tape, double-adhesive tape, foam tape, aluminum foil tape, clean tape, masking tape, etc. It also suitable for laminating different materials, such as non-woven, filter materials, shoes materials, medical material, label, film, etc.

2.lamination material requirement

1.Applicable coating film resin: Coating grade like LDPE, PP, EVA, EAA etc.

2.Based material: Non Woven Fabric, Paper (30~425g/m2 ) , Textile Fibre , Knited Mesh, BOPP, BOPET.

3.Inter-layer: Aluminium Foil, CPP, BOPP

3. Specifications

|

Model |

XD-L1100 |

XD-L1300 |

XD-L1600 |

XD-L1800 |

|

length of die lip |

1200(mm) |

1400(mm) |

1800(mm) |

2000(mm) |

|

Width of raw material |

500-1000mm |

600-1200mm |

800-1500mm |

900-1700mm |

|

Max. compounding speed |

100-150m/min |

100-150m/min |

100-150m/min |

100-150m/min |

|

Thickness of extrusion film |

0.01-0.1mm |

0.01-0.1mm |

0.01-0.1mm |

0.01-0.1mm |

|

L/D ratio of screw |

Φ95mm×30 |

Φ105mm×30 |

Φ120mm×32 |

Φ140mm×32 |

|

Max dia. of unwinding and rewinding |

Φ1300mm |

Φ1300mm |

Φ1300mm |

Φ1300mm |

|

overal size |

9600×8300×3200mm |

9600×8600×3200mm |

9600×9000×3200mm |

9600×9300×3200mm |

|

power |

70kw |

80kw |

100kw |

130kw |

|

cool roll for glossy /compound |

Φ510mm |

Φ510mm |

Φ510mm |

Φ510mm |

|

Applicable base material |

paper/nonwoven PP/Aluminum/ |

|||

4.Final product

|

|

5.Service

1. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

2, what about your installation service and sales service for machine?

Guarantee is one year, we will supply spare parts or send engineers to your side if you need, we will give you service anytime, 24 hours, 7days.

We already prepare technical manual and operation video to show our customers, then it will be easy to install and use the machine.

It is free to train your worker in our factory or in your side or by video.

3. How long is your machine’s warranty period?

All our machine have one year guarantee for electricity parts and two years guarantee for mechanism, starting from finished installation.

6.Our company

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Main non woven machine

Associate machine

Fine quality management pay attention to every detail of the equipment manufacturing process

We have established stringent spare parts quality management standards, some key spare parts use well-known foreign brands to ensure he high performance of each machine, low figure rate, durability, simple and convenient operation and maintenance, every detail from the customer’s consider the angle

Product detail pictures:

Related Product Guide:

We always do the job to be a tangible group making sure that we can provide you with the top top quality as well as ideal value for China High quality Pvc Blow Molding Machine Factory – Fabric Lamination Machine – Xinda , The product will supply to all over the world, such as: Cambodia, Congo, Japan, With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our products in China!

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.