Face Mask Making Machine

Face Mask Making MachineProcedure

Raw material feeding-> Nose clipfeeding->Welding the outline of the mask -> Mask Forming

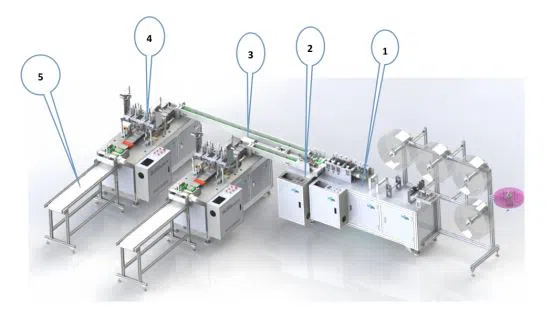

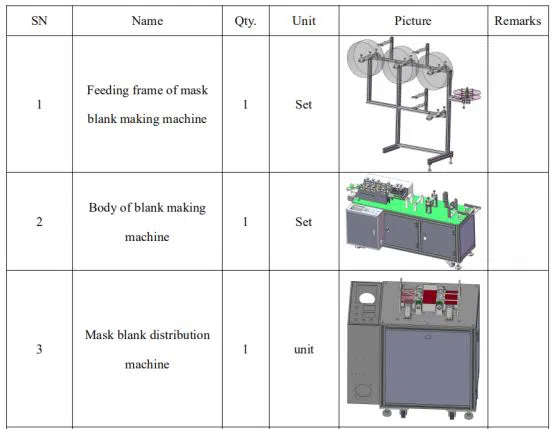

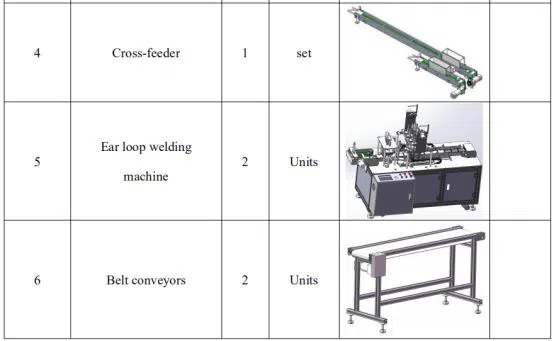

1. Film machine

2. Shunt

3. Bridge feeding machine

4. External ear welding machine

5. Belt conveyor

1. Machine Specification

| Ultrasonic | 20K |  |

| Touch Screen | WEINVIEW |  |

| Bridge Device | Better place the bridge of nose into the mask |  |

| Embossing Roller | Φ83MM |  |

| Cutter | Φ83MM |  |

| C45 Switch | CHINT |  |

| Contactor | CHINT |  |

| Three Fold Folding Knife | 1 SET |  |

| Conveying Table | Delivery mask |  |

2.Machine advantage

vMachine case body is made of aluminum alloy,rust and corrosion resistance,with a good antibacterial property。

vMask body and ear loop is welded by high quality ultrasonic,solder joint with high firmness and good look

v1+2 design (one main body +two ear loop welding device) can greatly improve the productivity and save space

vAutomatic stacker,reduce labor cost

vPlc control,easy to operate and high efficient

3.Samples:

4.Main parameter

| Model | XD-FM12 | Dimension | 6500*3500*1800MM |

| Capacity | 100-120pcs/min | Machine weight | 1600KG |

| Total power | 11KW | Detection method | Photoelectric |

5.Main configuration

| Main part | Description | Brand | Original |

| Machine case | Aluminum Alloy | China | |

| Electric control system | PLC | Panasonic | Japan |

| Servo motor | Inovance | China | |

| Power stabilizer | EMI power filter | Taiwan | |

| Power protection | Schneider | France | |

| Power supplier | Meanwell | Taiwan | |

| Switch | Schneider | France | |

| Welding system | Ultrasonic generator | Mingyou | Taiwan |

| Ultrasonic boost and transducer | |||

| horn | |||

| Pneumatic system | Air cylinder | Airtac | Taiwan |

| Pressure regulator | |||

| Solenoid valve | |||

| Air filter | SMC | Japan | |

| Transmission system | Guide rail | Hiwin | Taiwan |

| Bearing | NSK | Taiwan | |

| Gear motor | Dongma | Korea | |

| Running request | Power supply | AC220V±10%/50hz/ | |

| Air supply | 0.5-0.7Mpa |

Warnings and cautions

In order to avoid injury and damage to the product and its related products, please follow the safety warnings andprecautions below before use. To avoid potential danger, please use as specified.

Please follow the instructions specified in this guide, otherwise the protection provided by the device may be weakenedand damaged.

Install the device in a clean, dry and level environment and connect and remove it properly.

Use regular voltage and ground protection to prevent electric shock and other accidents.

In order not to cause special failures, please remove the electromagnetic substance to ensure that there is noelectromagnetic field around the product controller. Please do not operate in the presence of potential errors. If you are not sure that this will not cause damage to the equipment, please check with a professional Confirm it beforeproceeding.

Do not operate in explosive air.

Do not open the housing of the controller or module parts.

Safety Precautions

In order to use the product correctly and safely to prevent accidents, please read the “Safety Precautions” carefullybefore using.

Precautions are composed of “Warning” and “Caution” and other contents. For the corresponding detailed description,

please refer to the “mark description table” below.