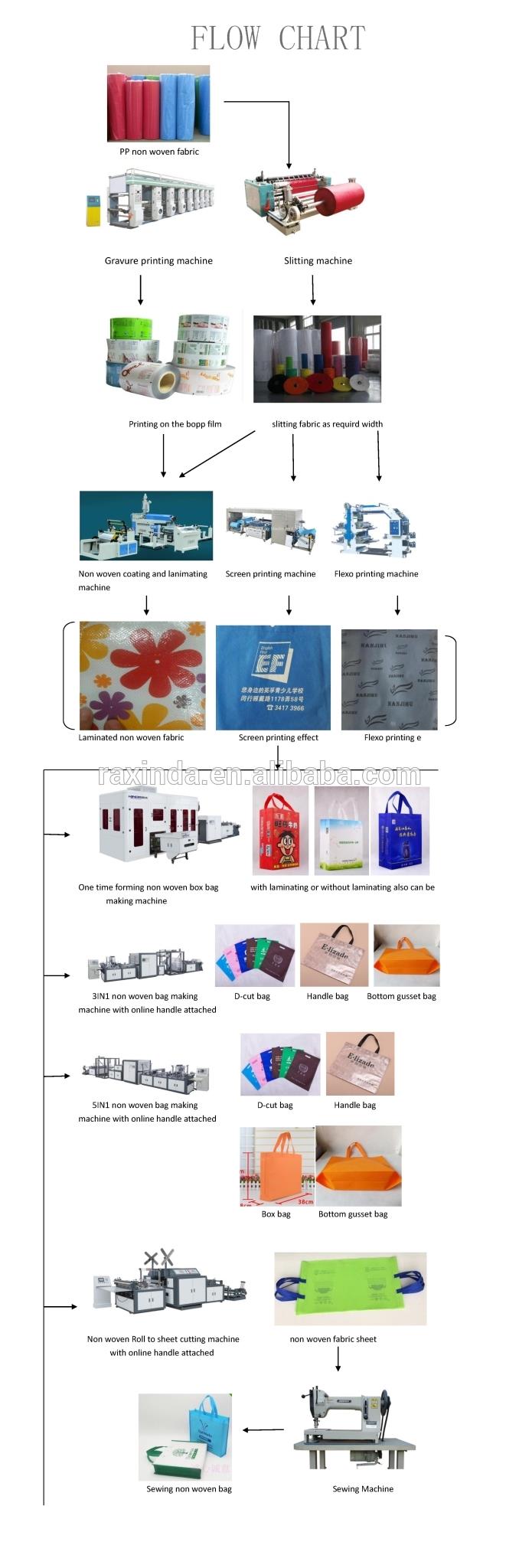

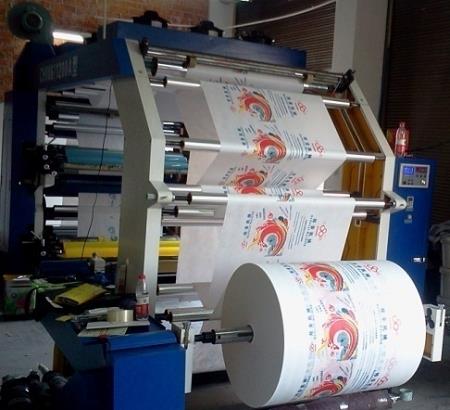

Flexo Printing Machine

Product name:

roll to roll Flexographic Printing Machine

1.PERFORMANCE AND CHARACTERISTICS:

This machine is suitable for printing such packing materials as polyethylene, polypropylene plastic bag, cellophane and roll paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag and clothes bag, etc.

1.Easy operation,flexible starting, accurate colour regicter.

2.The numeter counter can set printing quantity as required. Stop the machine automatically at the set quantity or when the material is cut off.

3.Lift and lower the printing plate cylinder manually. It will automatically stir the printing ink after lifting.

2.MAIN TECHNICAL PARAMETERS:

|

Model of Machine |

YT-4600 |

YT-4800 |

YT-41000 |

YT-41200 |

YT-41600 |

|

Max.Width of Printing Material |

600mm |

800mm |

1000mm |

1200mm |

1600mm |

|

Length Range of Printed |

191-1000mm |

191-1000mm |

191-1000mm |

191-1000mm |

191-1000mm |

|

Max. Diameter of Roll Material |

450mm |

450mm |

450mm |

450mm |

450mm |

|

Printing Speed |

5~50m/min |

5~50m/min |

5~50m/min |

5~50m/min |

5~50m/min |

|

Thickness of plate(Including Two-sided Glue Paper) |

2.38mm |

2.38mm |

2.38mm |

2.38mm |

2.38mm |

|

Total Power |

10kw |

12kw |

15kw |

18kw |

22kw |

|

Overall Dimensions(L*W*H) |

4300*1600*2400mm |

4300*1800*2400mm |

4300*2000*2700mm |

4500*2200*2700mm |

4500*2400*2700mm |

|

Weight |

3000kg |

3500kg |

4000kg |

4500kg |

5300kg |

3.Final product

|

|

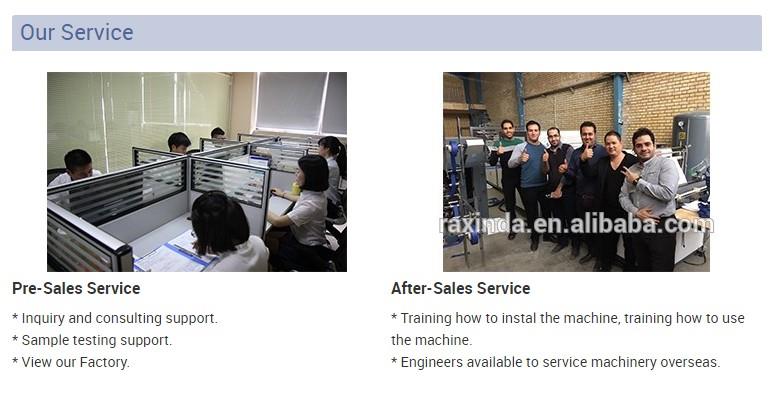

4.Service

Service:

1.Engineers provide overseas installation services,Until customers are familiar with independent operating machines.

2.24 hours maintenance hotline service to ensure the smooth production of customers.

3.Give away the right amount of vulnerable parts free of charge.

A.Lsupportsourcustomersservice24hoursAday,7dayswork,Anyinquirycould

berepliedwithin1hourpre-salesandafter-sales.

WeBelievethatonly:BestQualityMachineWithInnovativeIdeasandExcellentAfter-saleService:"shallmeetyourspecialrequirements.

TERMS OF DELIVERY AND PAYMENT

*Delivery Time:30working days at sight the deposit

*Transport Condition:FOB NINGBO PORT, CHINA

*Certification:CE

*Payment:T/T 30% deposit after sign the contract,70% balance before shipping date.

*Loading:one 40HFT container for shipping,film plastic around.Total weight 9000kg.(select parts more space)

5.Advantage

1. How many days will you finish installing ?

We will finish installation and training within 10 days.

2. What should we charge for your engineer?

You should charge for the cost of our engineer's air tickets, hotel,food,and also their salary 100USD one day per person.

3. How long is your machine's warranty period?

All our machine have one year guaranteefor electricity parts and two years guarantee for mechanism, starting from finished installation.

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag

Associate machine

Main non woven machine