Fully Automatic Non Woven Bag Machine

1.Main Introduction

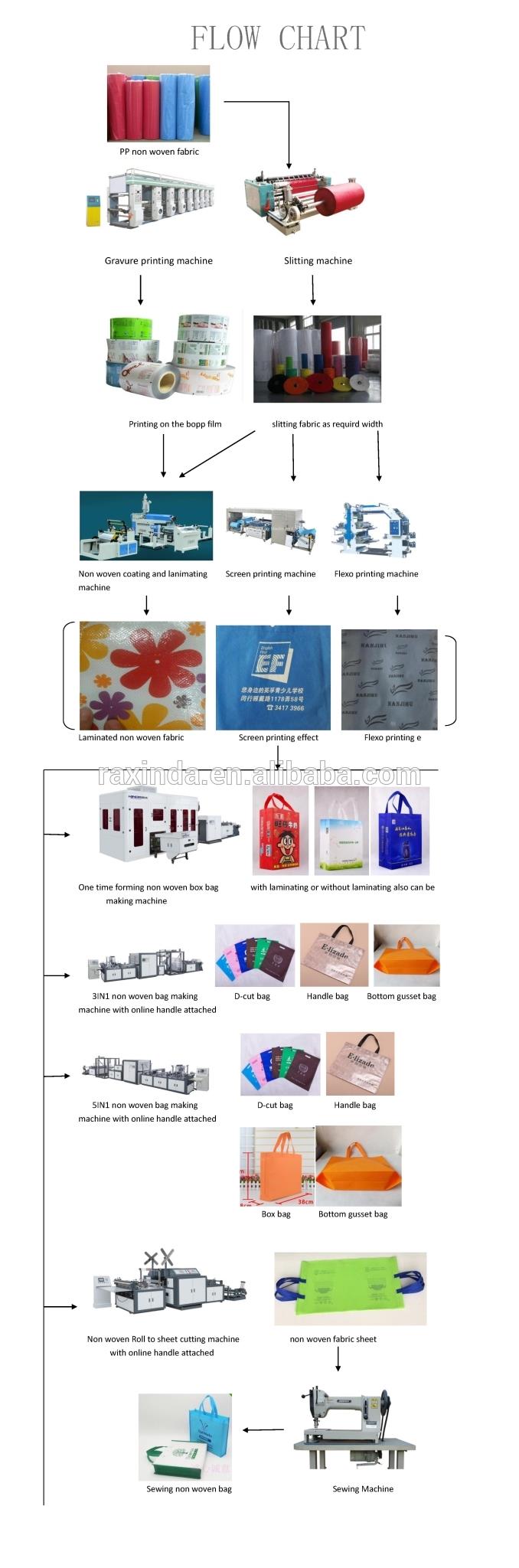

This machine can make non-woven, printing and non-printing gift bag, flat bag, handle bag, D-cut bag, draw string bag, pillow cover etc.

2.Main specification

|

Model |

WFB-D600 |

|

Max.Bag Making Width |

600mm |

|

Bag Making Thickness Range |

20-80g |

|

Max.Bag Making Length |

800mm |

|

Production Speed |

40-120pcs/min |

|

Total Power |

8kw |

|

Machine Weight |

2500kg |

|

Overall Demensions |

7800*1700*2000mm |

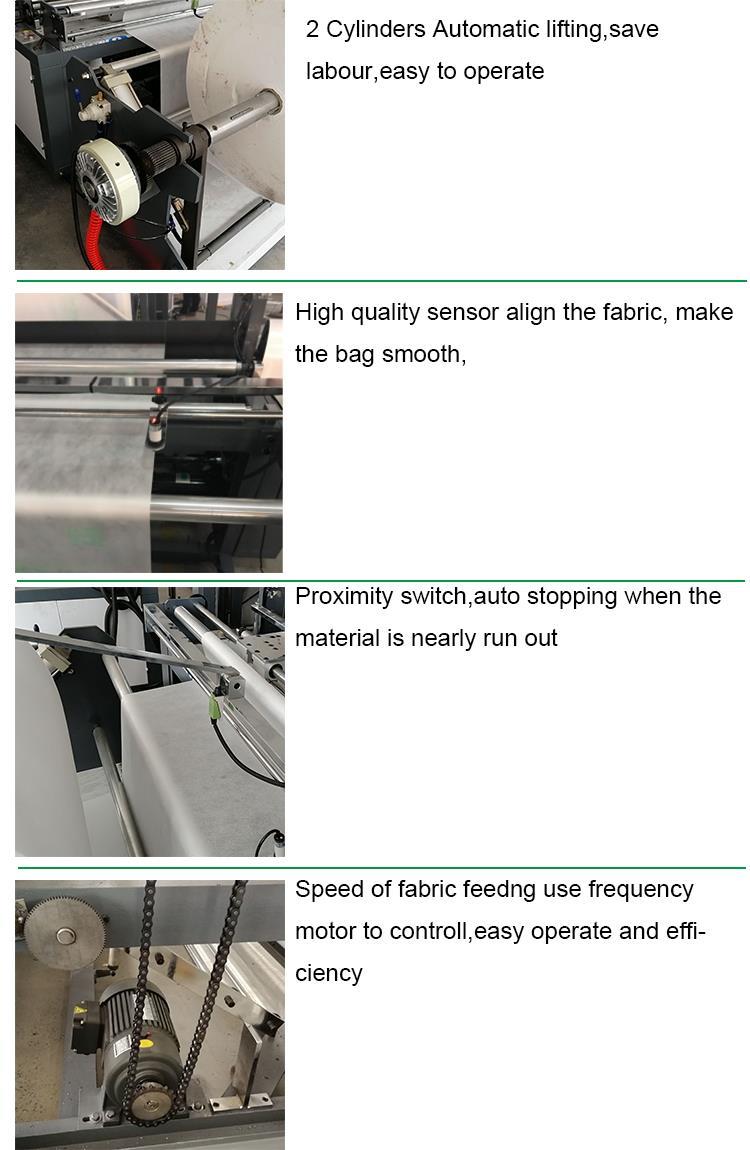

3.Main advantage and improvement

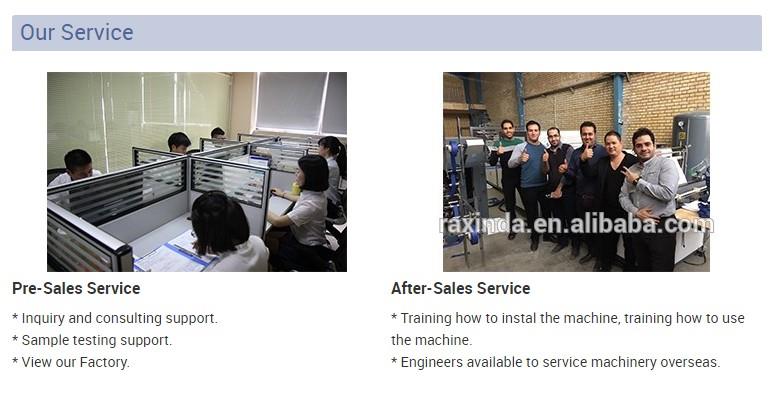

4.Service

Q1: Are you a trading company or a manufactory?

A1: We are a manufactory with more than ten years; we supply the factory price with top grade quality, and welcome to visitour factory.

Q2: What’s your guarantee or the warranty of the quality if we buy your machines?

A2: We offer you machines with 1 year guarantee and have engineer can go overseas supply life-long technical support.

Q3: When can I get my machine after I paid?

A3: The deliver time is based on your order, for general about 1-3 month.

Q4: How can I install my machine when it arrives?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines.

Q5: How about the spare parts?

A5: We will offer you a spare parts list for your reference, and will provide all parts when you need them.

5.Advantage

1. Does your engineer understand English?

Our engineers understand a little English. All our engineers have more than five years machine installation experience. In addition, they can use body language to communicate with customer.

2. Can you help us find any engineer in our location?

Of course, we will check and inform you as soon as possible.

3. How about your delivery time?

A: Generally, it will take 20 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

4, Where are you? Can we go to China and visit your factory?

Yes, of course.We are inNo.1068 Jingye Road, Dongshan Street, Ruian City, Zhejiang Province, China

Product advantages:

High Intensity:service life of more than 15 years.

Rot Resistance:suitable for different climates, every occasion.

Quick & Easy Installation:saving labor and financial resources.

Variety of Colors and Patterns:different color and pattern can be made as required.

Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary.

Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

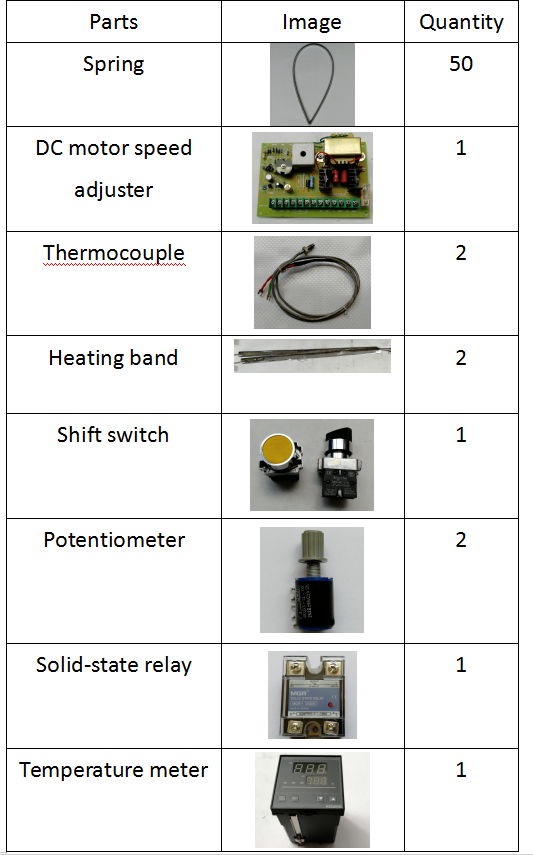

6.Spare parts for free

|

1.Spring,50 pieces |

100pcs |

| 2.DC speed-adjust board | 1 piece |

| 3.Thermocouple | 2 pieces |

| 4.Heating-piece | 2 pieces |

| 5.Shift switch | 1 pieces |

| 6.Potentiometer | 2 pieces |

| 7.Solid Contactor | 1 piece |

| 8.Thermometer | 1 piece |

| 9.Relay | 2pcs |

| 10.AC contactor | 1pcs |

| 11.Handle wheel | 1 pair |

| 12.Tool box | 1set

|

Main non woven machine

Bag sample

Optional machine ![]() unching equipment for U-cut bag

unching equipment for U-cut bag