Pp Woven Bag Machine

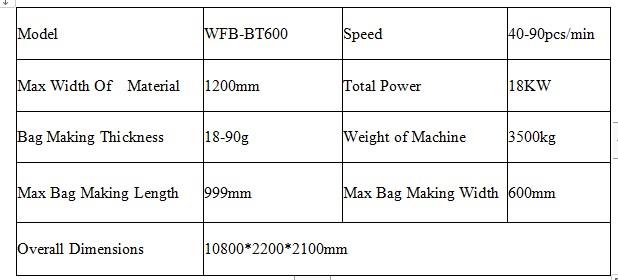

1.Main parameter

2.Detailed

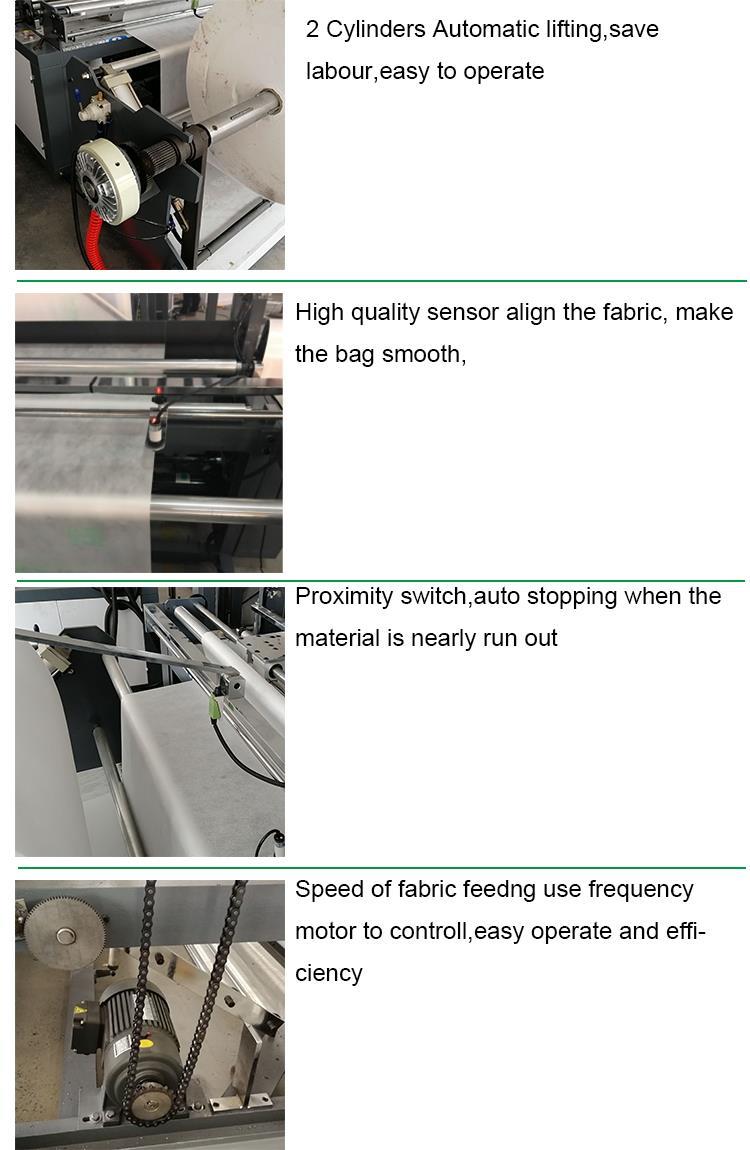

3.Advantage

a.Frequency conversion motor feeding, synchronous feeding with the host, one-button operation.

b.The cutter is made of imported steel, and its durability and service life are 20% longer

c.Four ultrasonic waves can be independently controlled, saving 5% of energy consumption and extending service life.

d.The length of the fuselage is 10% shorter than that of similar equipment, which reduces the tensile force in the traction of the cloth and the waste generated by debugging.

e.The ultrasonic welding head pressure adopts spring shock absorber, so the welding pressure is more even and the heat sealing effect is better.

4.Service

A. How many workers do we need running those machines?

Except Two for bag making machine, flexo printing, slitting, ultrasonic sewing, hydraulic punching machine only need one person for each.

B. How could you do if the parts broken within warranty?

We would express the free replacement parts during the warranty date.

C. How long will your engineer reach our factory?

Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc. Prepared)

D, Can you ship the machine to my address?

Yes, we will have a special overseas logistics transport to transport the machinery to your address.

E: How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit ;

We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

For the success of the first cooperation,we will give you the most favorable price.

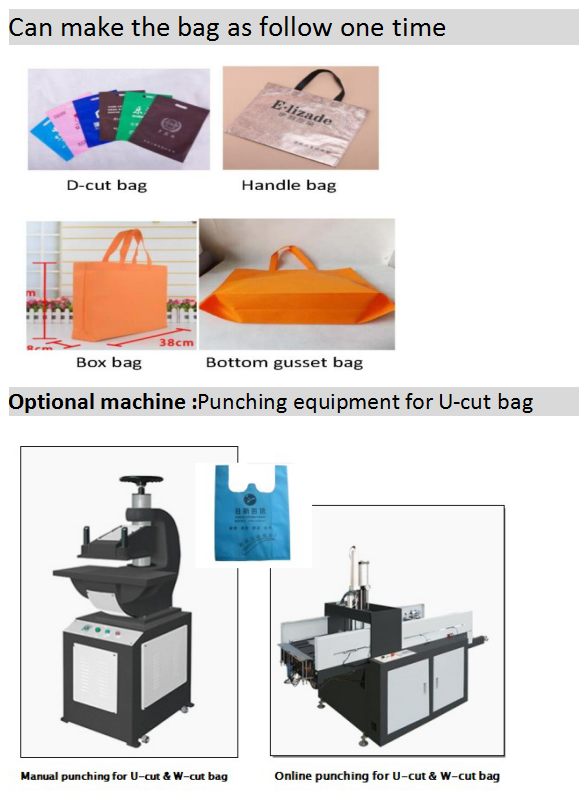

5.bag sample

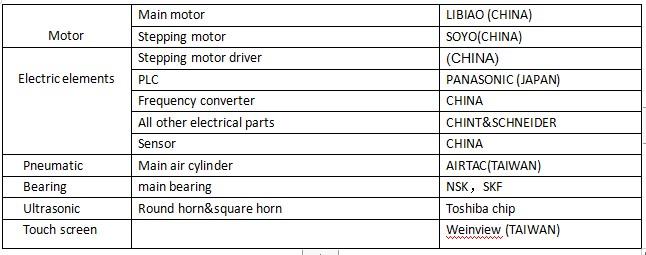

6.Main components

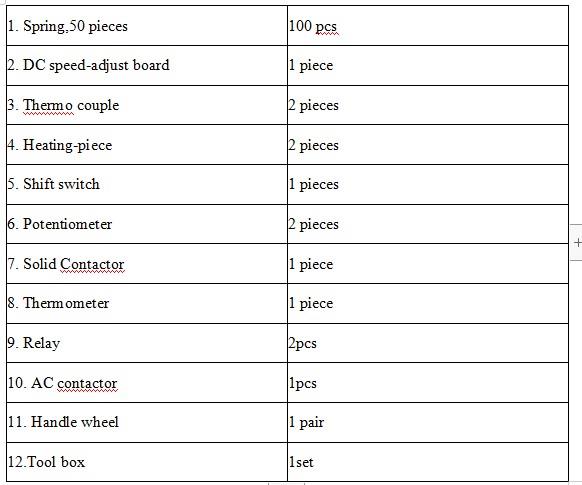

7.Spare parts for free